TexasZ

New member

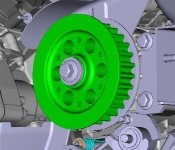

I was wondering about how the red dust was getting out to collect on the front side if the bolt was still tight as it should be.Sarge, that pic of yours in #143 shows red dust yet the pulley is tight on the shaft you say. This was found also to be the case on some 990 failures. The pulley was worn but the wear misaligned the splines for easy removal - just a point of interest or confusion as the case may be. That red dust is bleeding from behind the large washer.

Like you mentioned before about the BRP loctite on the bolts keeping the bolts from torquing down correctly, I noticed EETHER54 coming to the same conclusion...

After hearing that from both of you, I'm wondering whether we might be better off to remove the BRP loctite from the new bolt and put some fresh Loctite on and immediately install and torque the bolt down before the loctite has a chance to harden up and interfere with the torque specs.The red rust isn't the cause of the issue, it's just a byproduct of the spines failing. There is no real sort of coating on the sprocket splines, just bare on bare metal. Our first F3 that had complete spline failure was a manual shift, so I'm not sure how strong the correlation between the SE6 clunk and the issue is. Our shop hasn't seen this specific type of failure on the 1330 RTs at this point.

IMHO I believe there is less bearing surface between the backside of the sprocket and the shaft as compared to the 990 engine. This coupled with improper torque of the bolt likely exacerbated by BRP's somewhat irritating habit of preloading bolts with loctite is what is causing the issue. What I have observed would seem to indicate the design relies heavily on arresting any movement with solely the tension of the bolt. If it isn't torqued properly it eventually allows movement of the splines and it's all downhill from there.

The loctite 660 is designed to arrest any potential for movement, frankly making the clamping force of the bolt much less important. I understand that heat will have to be used to remove the sprocket eventually, but that really isn't something that you should have to replace that often. Replacing the seal behind it would not be that difficult as infrequently as this operation would need to be undertaken. Fwiw, certain years of ZX6s came from the factory with a obscenely tight front sprocket nut. The advice from the kawasaki tech department was to heat the nut red hot and hit it with an impact gun. The seal obviously needed to be replaced but there was never another issue...

While there may be more than one way to fix the issue, I would recommend anyone still under warranty to go the loctite route, or rather, make sure that your dealership does so for you.

Torque specs for the 1330 call for 92 pounds + or -4. I would definitely go for the 92+4.

Last edited: