-

There were many reasons for the change of the site software, the biggest was security. The age of the old software also meant no server updates for certain programs. There are many benefits to the new software, one of the biggest is the mobile functionality. Ill fix up some stuff in the coming days, we'll also try to get some of the old addons back or the data imported back into the site like the garage. To create a thread or to reply with a post is basically the same as it was in the prior software. The default style of the site is light colored, but i temporarily added a darker colored style, to change you can find a link at the bottom of the site.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

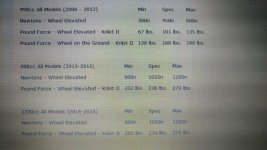

Belt tension, N vs lbft

- Thread starter johnv50

- Start date

trikermutha

Active member

Then tension goes back up when on the ground.

Purple Guy

New member

BLUEKNIGHT911

Sadly Passed Oct 2024 - RIP

I know that 625n equals about 140 lbf, but if belt tension is set in the air as per BRP specs to 625n,(spec is 775n + or - 150n)

will that tension go up or down with the wheel back on the ground, checked with a Krikit gauge ??

thanks johnv

Ron's chart shows the KritKit gauge reading needs to be LOWER if the wheel is OFF the ground .... I like 160 +/- lbs. ON -the-ground, I can't feel any Belt vibes .... On the ground checking, saves a Ton of time and effort, and if you use the right Lbs. amount .... you achieve the SAME thing ..... good luck .... Mike :thumbup:

WDAVEY

Member

Please be gentle, I'm new at this lbf vs n thing. I have a 2019 RTL with 4,500 miles. I get a slight "beat frequency" vibration most noticeable at 72 mph. My repeated readings on Krikit is 230# WOG. If I understand all the explanations above it should only be about 160#WOG. I just want to know the target before I start adjusting. TIA for your help.

BLUEKNIGHT911

Sadly Passed Oct 2024 - RIP

Please be gentle, I'm new at this lbf vs n thing. I have a 2019 RTL with 4,500 miles. I get a slight "beat frequency" vibration most noticeable at 72 mph. My repeated readings on Krikit is 230# WOG. If I understand all the explanations above it should only be about 160#WOG. I just want to know the target before I start adjusting. TIA for your help.

If " WOG " is While On Ground :roflblack:..then you are correct 160 lbs. +/- is what I have mine at ..... Mike :thumbup:

PMK

Active member

Please be gentle, I'm new at this lbf vs n thing. I have a 2019 RTL with 4,500 miles. I get a slight "beat frequency" vibration most noticeable at 72 mph. My repeated readings on Krikit is 230# WOG. If I understand all the explanations above it should only be about 160#WOG. I just want to know the target before I start adjusting. TIA for your help.

There is no approved spec for belt tension with weight on wheels. By jacking and tensioning the belt with no weight on the rear wheel, the suspension is at full extension, AND a repeatable position.

Weight on wheels measurements can vary based on the true ride height. On some years with adjustable rear suspension, you could find that there is inconsistency between each person Spyder regarding actual belt tension per the manuals procedure if set with weight on the wheels.

Most people that set their belt tension to the median spec of the TSB, measured with the suspension fully extended have had good results that are easily repratable.

Mikey

Well-known member

So what your saying is that the more you load the suspension, the tighter it will get!! So if they are looking for a happy spot for the whole system, bearings, belt, ect, would it not be smarter to do that under a normal load set up? You take the bike, lift it, set it, then load it, and every one carry's different stuff, you don't really know what you got for shore on the belt!

BLUEKNIGHT911

Sadly Passed Oct 2024 - RIP

There is no approved spec for belt tension with weight on wheels. By jacking and tensioning the belt with no weight on the rear wheel, the suspension is at full extension, AND a repeatable position.

Weight on wheels measurements can vary based on the true ride height. On some years with adjustable rear suspension, you could find that there is inconsistency between each person Spyder regarding actual belt tension per the manuals procedure if set with weight on the wheels.

Most people that set their belt tension to the median spec of the TSB, measured with the suspension fully extended have had good results that are easily repratable.

Interesting ..... if your hypothesis is correct, when you take your measurements do you load up the Spyder with the same amount of weight that you expect to carry on that days rides ???? .... and what if that weight changes during the ride, do you then re-measure it ???? ... When I lowered my Belt tension ( because it was way to high from the Dealership ) I first did it with wheel OFF the ground, after I lowered the spyder to ON the ground, I took that measurement. .... Now I had TWO lb. amounts that Equaled each other depending if it was OFF the ground or ON the ground..... I also don't use the " approved " BRP method of measuring the oil, I only check it AFTER I ride for more than 10 minutes. .... I guess I'm just a " rebel " :thumbup: :clap: ........... Mike :thumbup:

PMK

Active member

Interesting ..... if your hypothesis is correct, when you take your measurements do you load up the Spyder with the same amount of weight that you expect to carry on that days rides ???? .... and what if that weight changes during the ride, do you then re-measure it ???? ... When I lowered my Belt tension ( because it was way to high from the Dealership ) I first did it with wheel OFF the ground, after I lowered the spyder to ON the ground, I took that measurement. .... Now I had TWO lb. amounts that Equaled each other depending if it was OFF the ground or ON the ground..... I also don't use the " approved " BRP method of measuring the oil, I only check it AFTER I ride for more than 10 minutes. .... I guess I'm just a " rebel " :thumbup: :clap: ........... Mike :thumbup:

Setting belt tension on the ground does work for you. You have experimented and determined your best on the ground setting.

The maintenance manuals, accommodate the majority of owners, since most go to the dealership, and the dealer techs would not be able to contend with having owners in the shop as they tinker with optimizing belt tension for each owner.

With that, they determined a tension that can be repeated each time the rear wheel is removed or tension is set.

As we know, they did release a service bulletin regarding belt tension. Those that have reset to the lower belt tension spec range, following the maintenance manual method with weight off the rear wheel typically have had good results.

As for you being a Rebel, living North of the Mason Dixon generally rules that out. Seems you are more like Doc from Back To The Future. Tinkering with something.

PMK

Active member

So what your saying is that the more you load the suspension, the tighter it will get!! So if they are looking for a happy spot for the whole system, bearings, belt, ect, would it not be smarter to do that under a normal load set up? You take the bike, lift it, set it, then load it, and every one carry's different stuff, you don't really know what you got for shore on the belt!

It could be better to have a loaded weight on wheels spec for belt tension. Unfortunately no tech would even be bothered setting to those requirements working flat rate pay.

Jack the Spyder set the tension to a manufacturers spec, lower Spyder and done. In theory, this works for the majority of riders that are average size carrying average stuff in the frunk, trunk and side bags.

All the best however you decide what works for you.

Set ours to the median spec per the bulletin, using rear wheel off the ground, and essentially no vibration 99% of the time.

WDAVEY

Member

If " WOG " is While On Ground :roflblack:..then you are correct 160 lbs. +/- is what I have mine at ..... Mike :thumbup:

Thank you for an explanation that even I can understand. I'll try the 160 lbs and see what happens.

WDAVEY

Member

Thank you for an explanation that even I can understand. I'll try the 160 lbs and see what happens.

Well, I tried it at 160lbs and the vibration was gone at 72 MPH! But it vibrated like crazy at 44 MPH. Here's my theory- the belt is like a guitar string, the tighter it gets, the higher the frequency at which it vibrates. Lowering my tension merely lowered the frequency. As proof of my theory I raised the tension back up to 200lbs on the ground. Now it vibrates at 58-60 MPH. Sooooo, tomorrow I will install the tensioner (more like a vibration damper). I'll let everyone know my results.

BajaRon

Well-known member

Well, I tried it at 160lbs and the vibration was gone at 72 MPH! But it vibrated like crazy at 44 MPH. Here's my theory- the belt is like a guitar string, the tighter it gets, the higher the frequency at which it vibrates. Lowering my tension merely lowered the frequency. As proof of my theory I raised the tension back up to 200lbs on the ground. Now it vibrates at 58-60 MPH. Sooooo, tomorrow I will install the tensioner (more like a vibration damper). I'll let everyone know my results.

It takes awhile for the belt to settle into the new tension setting. More time the larger the change. I am not saying the vibration will go away. But you might want to give the belt some miles at a the current tension before making final judgement.

WDAVEY

Member

Well, I tried it at 160lbs and the vibration was gone at 72 MPH! But it vibrated like crazy at 44 MPH. Here's my theory- the belt is like a guitar string, the tighter it gets, the higher the frequency at which it vibrates. Lowering my tension merely lowered the frequency. As proof of my theory I raised the tension back up to 200lbs on the ground. Now it vibrates at 58-60 MPH. Sooooo, tomorrow I will install the tensioner (more like a vibration damper). I'll let everyone know my results.

Well, I installed the tensioner. What a CF! I think I used every tool in the garage and a trip to Harbor Freight. The bolts that came out of the frame tube to footboard bracket refused to go back into the holes they came out of. After about 4 hours I finally got all three bolts started and tight but I had to take the spring and roller arm off the tensioner bracket. then installed the arm, spring and roller after the bolts were in the correct holes and not cross-threaded.

Now for the results- no vibration at 60 or 72 MPH, but I still have vibration at about 45. Second guessing myself, maybe it always did this and I'm paying more attention now. So my new plan is to just drive the thing and quit worrying about any minor vibration.

trikermutha

Active member

Once a tensioner is installed isn't it recommended to lower the belt tension a bit??

PMK

Active member

Well, I installed the tensioner. What a CF! I think I used every tool in the garage and a trip to Harbor Freight. The bolts that came out of the frame tube to footboard bracket refused to go back into the holes they came out of. After about 4 hours I finally got all three bolts started and tight but I had to take the spring and roller arm off the tensioner bracket. then installed the arm, spring and roller after the bolts were in the correct holes and not cross-threaded.

Now for the results- no vibration at 60 or 72 MPH, but I still have vibration at about 45. Second guessing myself, maybe it always did this and I'm paying more attention now. So my new plan is to just drive the thing and quit worrying about any minor vibration.

Regarding the vibration at lower speeds, are you rolling on aftermarket automotive tires in the front and rear, or are you still rolling on the stock Kenda tires?

WDAVEY

Member

Regarding the vibration at lower speeds, are you rolling on aftermarket automotive tires in the front and rear, or are you still rolling on the stock Kenda tires?

Stock Kendas, only 4700 miles on it. BTW I just realized my Gravely zero turn lawn mower has Kenda tires!

Similar threads

- Replies

- 39

- Views

- 5K

- Replies

- 7

- Views

- 2K

- Replies

- 37

- Views

- 9K

- Replies

- 80

- Views

- 29K