Gwolf

Well-known member

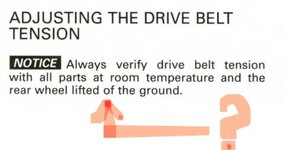

It is not about the belt tension. It is about the consistency of the readings.I have run 120 - 140 via the Krikit with the vehicle loaded/sitting on the ground for over 10 years. Especially when the engine mounted drive sprockets were failing and some transmission shafts, prior to a solution from BRP. The swing arm geometry increases belt tension as it is compressed. That's why many people recommend removing the rear shock bolt to drop the swing arm while changing a tire (vs slacking off the belt tensioners). Prove it to yourself: check tension with rear wheel in the air and with the machine on the ground: the Krikit value will increase 20-30 lbs.

The Can Am guidelines say to go by the manual to determine if the rear wheel should be hanging from the suspension or if it should be sitting on the floor. The belt tension numbers in the manual will depend on that.

Can Am has been wrong before and changed the numbers and other things. I guess all you can do is read the manual and then decide for yourself. That information should be in the Service And Repair Manual for your model and year. It is not likely to be the same for all Spyders because of the different belts used.

Last edited: