pontow

New member

I had the honor of being Doc's tester for the Side Case Strengthener Kit on a 2015 RT-S. There have been a few discoveries and tweaks along the way but here is my general report.I think this kit will work for its intended purpose. Doc is going to make a few minor changes but the design appears to do the job.

I also found the original instructions somewhat confusing. I'll try to decipher that a little bit right now. For those of you who have not actually experienced a hinge area failure (which I have not), you may find the descriptions a little hard to visualize. In essence, Doc's kit will include the hardware that will strengthen the hinge area by making a metal sandwich from one side of the hinge to the other. This "sandwich" will cover more of the plastic area to spread out the load put onto the plastic area by the metal hinges.

The area to be repaired is the half of the hinges (2 hinges in each side case, 4 hinges total) that connects to the fixed portion of each side case. The half of the hinge that connects to the moveable side case lid does not get changed in any way.

There is a springy, sheet metal bracket supplied for each hinge. It is the one with the intricate bends. This bracket will go directly on top of the existing hinge on the inside of the side case. You remove the existing bolts and bolt this bracket down over the existing hinge using the longer bolts that Doc supplies. The purpose of these brackets is to spread the load to a greater area than just directly underneath the hinge itself. The far left and right tabs that Doc has bent into these brackets will hopefully come into contact with the plastic area of the side case on both the left and right side of the pocket that the hinge sits in. This is the most fiddly part of the entire installation. You may very well find it necessary to "custom fit" these brackets by bending a little bit of a tweak into the outer tab area in order to make sure that it makes contact with the side case plastic and therefore does its job. The variation in the shape and dimensions of year to year side cases and possibly even one machine to the next means that this tweaking will quite possibly be a part of the installation process. Once we figured this out however it was not a big thing to do.

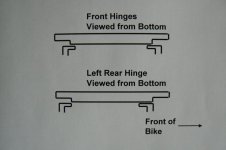

So, you remove the stock bolts from the hinge on the fixed side of the case (don't push out the backing plate on the back side - that's why Doc suggests doing one bolt at a time), put in the proper bracket that Doc supplies (note that the brackets have specific locations for front, back, left and right as well as up and down and Doc marks these) and then bolt down the new brackets over the existing hinge using the longer bolts that Doc supplies. On the backside of the case (between the case and the frame of the bike), these bolts are threading into the existing OEM backing plates.

Once that is done, then you add the other half of the "sandwich" that Doc supplies. It is a new backing plate that goes over the existing backing plate. It slips over the protruding bolts and gets nutted into place. There is a step that Doc has milled onto each end of the plate. This milled face goes against the face of the original backing plate. It allows the two backing plates to be a face to face contact and then provides for a "clamping action" over the top of the plastic "barbs" that help to hold the original backing plate into position. By having the new backing plate pushing down on the top of these "barbs", that is how he is spreading some of the load on the backside of the hinge connection area.

Overall, I think this is a good fix and is basically 8 old bolts out, 8 new bolts in and 8 additional nuts (together with the new brackets and backing plates). With some tweaking in betrween.

For you 2015 owners I have another suggestion which I did not do but probably should have. Doc tells me that the muffler has been repositioned on the 2015 to be up higher. This puts it closer to the bottom side of the side case and limits the access you have in this area. I have long skinny fingers and it was still a bit of a contortionist act to get to the backside of the hinge area behind the right side cases. It appears that the muffler heat shield will come off with just the removal of (3) bolts. If this is the case, you may want to remove that to give you some more room.

Farkle On!!

I also found the original instructions somewhat confusing. I'll try to decipher that a little bit right now. For those of you who have not actually experienced a hinge area failure (which I have not), you may find the descriptions a little hard to visualize. In essence, Doc's kit will include the hardware that will strengthen the hinge area by making a metal sandwich from one side of the hinge to the other. This "sandwich" will cover more of the plastic area to spread out the load put onto the plastic area by the metal hinges.

The area to be repaired is the half of the hinges (2 hinges in each side case, 4 hinges total) that connects to the fixed portion of each side case. The half of the hinge that connects to the moveable side case lid does not get changed in any way.

There is a springy, sheet metal bracket supplied for each hinge. It is the one with the intricate bends. This bracket will go directly on top of the existing hinge on the inside of the side case. You remove the existing bolts and bolt this bracket down over the existing hinge using the longer bolts that Doc supplies. The purpose of these brackets is to spread the load to a greater area than just directly underneath the hinge itself. The far left and right tabs that Doc has bent into these brackets will hopefully come into contact with the plastic area of the side case on both the left and right side of the pocket that the hinge sits in. This is the most fiddly part of the entire installation. You may very well find it necessary to "custom fit" these brackets by bending a little bit of a tweak into the outer tab area in order to make sure that it makes contact with the side case plastic and therefore does its job. The variation in the shape and dimensions of year to year side cases and possibly even one machine to the next means that this tweaking will quite possibly be a part of the installation process. Once we figured this out however it was not a big thing to do.

So, you remove the stock bolts from the hinge on the fixed side of the case (don't push out the backing plate on the back side - that's why Doc suggests doing one bolt at a time), put in the proper bracket that Doc supplies (note that the brackets have specific locations for front, back, left and right as well as up and down and Doc marks these) and then bolt down the new brackets over the existing hinge using the longer bolts that Doc supplies. On the backside of the case (between the case and the frame of the bike), these bolts are threading into the existing OEM backing plates.

Once that is done, then you add the other half of the "sandwich" that Doc supplies. It is a new backing plate that goes over the existing backing plate. It slips over the protruding bolts and gets nutted into place. There is a step that Doc has milled onto each end of the plate. This milled face goes against the face of the original backing plate. It allows the two backing plates to be a face to face contact and then provides for a "clamping action" over the top of the plastic "barbs" that help to hold the original backing plate into position. By having the new backing plate pushing down on the top of these "barbs", that is how he is spreading some of the load on the backside of the hinge connection area.

Overall, I think this is a good fix and is basically 8 old bolts out, 8 new bolts in and 8 additional nuts (together with the new brackets and backing plates). With some tweaking in betrween.

For you 2015 owners I have another suggestion which I did not do but probably should have. Doc tells me that the muffler has been repositioned on the 2015 to be up higher. This puts it closer to the bottom side of the side case and limits the access you have in this area. I have long skinny fingers and it was still a bit of a contortionist act to get to the backside of the hinge area behind the right side cases. It appears that the muffler heat shield will come off with just the removal of (3) bolts. If this is the case, you may want to remove that to give you some more room.

Farkle On!!

Attachments

Last edited: