SpyderAccessories Arm Replacement

It has been asked if the CanAmSpyderAccessories.com arm is equal to the one from NoBoot. Well, here is my report. (Caused by the breaking of the support arm on my 2011 RT-S)

It seems that Ron (NOBOOT) either does not have any more, or maybe they are several weeks out, and the eBay listing is expired, so I went with the SpyderAccessories version because of the turnaround time. It is more expensive (200 + shipping, but I had it in just a few days.

It DOES NOT COME WITH THE WEDGES TO REMOVE THE GEAR!!!!!!!!!!!!!!!! This makes the install a lot more difficult to say the least. Getting the bike apart is not a problem, but getting that gear off of the shaft was nothing short of a monumental task. To start with, the head of the small screw at the end of the shaft broke off as soon as I tried to remove it. There is no information that says if that screw slips inside the gear and into a threaded part of the shaft or if the threads are also in the plastic part of the gear as well, but the gear did not move no matter what i tried. So I drilled out the screw, and still had no joy in getting the gear off. I tried to use the original arm as a "ram" to force off the pulley. I tried several ways to get some force the gear, but nothing seem to get it moving. Finally, I applied some heat and used a "punch" in the hole where the screw was and was able to drive the shaft out of the gear assembly. Not fun, and more than a bit nerve wracking. If I destroyed the thing, then I was looking at multiple hundreds of dollars for a new unit plus the cost of the new arm.

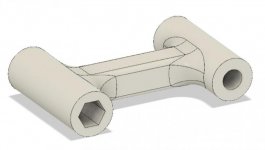

Re-assembly was not too bad, but..... The gear is shaped like the hex shaft inside, and fits just as tight when replacing it as it did taking it off. I think the screw is unnecessary (I hope), so I did not try to drill and tap the shaft but just pressed the gear back on the shaft. The shaft housing has a capped end, so there is nowhere for the gear to go even if does shift. Time will tell!!

The new arm does not allow for the use of the small plastic washers at the windshield end. No big deal as the new part fits better inside the support frame without the washers than the old one does with them!! The new arm also does not use the roll pins to hold it on the shaft. Instead, it uses a set screw with an allen head. The inside of the arm is cut to fit the hex shaft, so the set screw is only used to keep it from moving side to side.

There were no instructions or pictures with this setup. I forget what the size is for the allen wrench, but it comes from Canada, so it was metric. Nothing said I should, but I decided to add some locktite to this screw as I did not want to even think about looking for it if it came loose.

All in all, the product is really well made, and should outlast the bike.

I did post a review to SpyderAccessories, indicating that it would certainly be better if it came with some instructions, a note about the size of the allen wrench, and even better with the wedges!! It is a great product, but not a project for the faint of heart.

As an FYI: When the job was done, the windshield works great! In fact, it does not "wobble" near as much as the original because the tolerances between the arm and the windshield support frame are much tighter! Overall, I am pleased, and really thankful to be done with this project!! It took many hours, and a lot of experimenting, but is a big improvement over the original.

In the spirit of full disclosure: When prying the right side cap off of the shaft, it popped up and then disappeared down one of the many openings into the darkness of the front of the bike. It took nearly 2 hours of looking, removing panels that I had no original intention of removing, and mounting fears about what might be needed if I could not find it!! I eventually used a Ryobi Inspection camera attached to my phone, and with the help of the Spyder Gods found the part lying inside of the U-channel on one of the frame pieces. With the help of a long retrieval tool, I was able to liberate it from the depths and continue on with the project. Just a reminder to be sure to block all of the holes with rags or something when doing this kind of work. This is especially important when replacing the C clips on the windshield frame! You do not want to take the bike all apart to look for them if they disappear.

Follow Up:

I received a call today from Pierre at SpyderAccessories today. He was following up on my review. His operation is really the essence of the Small Business community. It is just him and his significant other doing everything!! Since he does not make these arms, and does not want to infringe on any patents or other liability areas, he just has them made by a local craftsman - (who used to be a tech at BRP and now works as his own repair shop) and markets them to the public, so there is no expectation of videos, directions, wedges, or any additional support. He was really great to talk with, and offered to be of any assistance he could for future purchases, questions, and observations.