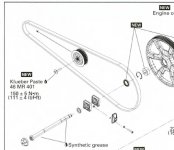

Progress Update: Well, Folks, I picked up my Spyder from my Dealer today, and put 100 miles on it after they did another “ FIX” on Warrantee per BRP Factory instructions. My diagnosis was correct. The Sprocket splines were stripped again, so BRP authorized another new Sprocket, supposedly improved over the last two that failed. This one is hardened, according to BRP so should last longer. They also changed the Bolt, and used what ever “ Gorilla Glue” on the shaft and Sprocket mating splines as BRP supplied. The Dealer supplied BRP with photos as they were deciding what to do. As others have posted, the Dealer first could not figure out how to get the Sprocket off the shaft, as it was frozen on. So they had the engine all unbolted to be removed from the frame, and they planned to split the Case and remove the entire shaft. But BRP came up with a solution how to remove the Sprocket from the shaft , with out removing the engine. They finally succeeded, and I guess BRP looked at the shaft photos and decided the shaft splines were not damaged enough to replace the shaft. So it appears, they did the EXACT same “FIX” as they did a year ago, that lasted 12,000 miles. But if this Sprocket is a new designed hardened Sprocket, than time will tell how long this one will last. But I have decided to purchase the 3 year Extended B.E.S.T. Warrantee when the Factory Warrantee soon expires. I expect this Sprocket failure issue to resurface again. So, this time, my Spyder was tied up 2-1/2 months again, the same as last Summer. My Harley has been getting the attention, but I just bought a new Red Chevy Camaro 2SS with 455 H.P. with every Bell & Whistle option available. So, life must go on, while sick Spyders are in the Hospital.