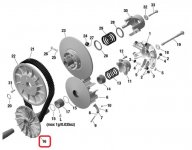

I got a transmission service warning indicator at 11600 miles. I change the belt myself. It was a little bit of a pain to get the cover off, but other than that, not too terrible. My old belt looked quite good showing little signs of wear despite the fact that I did have a belt overheating issue on one occasion due to a dirty filter.

From the looks of my belt, I think it could have made it easily another 10000 miles.

So do you think that BRP is just doing a little CYA by recommending replacement every 12000 miles?

I'm not worried about the cost of the belt if in fact it can go 20,000 miles. I am concerned about how often I have to change the CVT air filter. I do not drive-in terribly dirty conditions and I was having to replace my filter every 3 to 4000 miles. So, I eventually put a K&N filter on and that pretty well solves that problem.

Thoughts on real CVT belt life???

From the looks of my belt, I think it could have made it easily another 10000 miles.

So do you think that BRP is just doing a little CYA by recommending replacement every 12000 miles?

I'm not worried about the cost of the belt if in fact it can go 20,000 miles. I am concerned about how often I have to change the CVT air filter. I do not drive-in terribly dirty conditions and I was having to replace my filter every 3 to 4000 miles. So, I eventually put a K&N filter on and that pretty well solves that problem.

Thoughts on real CVT belt life???