canamryder

New member

Thanks

Thanks for the(more)info. I also upgraded the plugs to NGK CR8EIX 4218. I will go out soon for a couple smiles. :yes: BTW I had to raise the Clam Shell to get the front plug out.

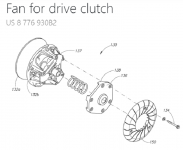

Just to be clear, the CVT fan has nothing to do with the coolant fan. While you are able to hear the coolant fan cycle on and off. The CVT fan is always spinning whenever the engine is running. Since the CVT fan is located on the drive side of the CVT system, it will turn at engine RPM speed regardless of belt or outside air temps.

Part #16 in this diagram is surely the fan, though BRP designates it as an 'Inner Half Assembly'. But you can see the classic centrifugal impeller design on this part.

View attachment 181494

What is not clear to me (Opening up my CVT drive system may clear this up) is whether this fan merely circulates air within the assembly (not likely. You wouldn't need a scoop or air filter for this, I don't think) or sucks in air through the intake and blows it out through an exhaust port (which is much more likely the case).

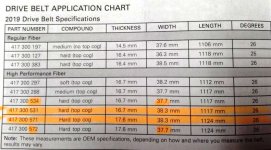

I feel that the large increase in air volume that the K&N can flow to this cooling system will definitely be a big advantage. Not to mention the savings over the OEM paper, throw away filter and, hopefully, extended belt life.

Thanks for the(more)info. I also upgraded the plugs to NGK CR8EIX 4218. I will go out soon for a couple smiles. :yes: BTW I had to raise the Clam Shell to get the front plug out.