JCGammack

New member

Here is the trailer I put together

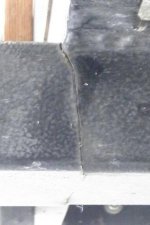

Here is my trailer project. Used a Harbor Freight Tool trailer kit. I used the 1000# rated kit because it has 12" wheels. I had already had the car top carrier and had adapted the box to a Thule roof rack and used it on many cars and vans over the years. So not having deep pockets I have now adapted this setup to the trailer. I used 1 1/2" angle and 3/4" angle to create the profile of a rain gutter for the roof rack feet to attach. Small blocks of 3/4" square stock are to support the 3/4" angle. Found a company to Power Coat the rails for around $50.00 also they did the frame for the cooler rack for $25.00.

It has worked out that the gap between the trailer bed and the car top box is a great place to put tent and folding chairs.

The trailer is rated for much heaver loads that I would use for motorcycle towing. To soften the trailer I removed some of the leafs from the springs. This seems to be working out fine.

Here are some pictures of my finished trailer.

Here is my trailer project. Used a Harbor Freight Tool trailer kit. I used the 1000# rated kit because it has 12" wheels. I had already had the car top carrier and had adapted the box to a Thule roof rack and used it on many cars and vans over the years. So not having deep pockets I have now adapted this setup to the trailer. I used 1 1/2" angle and 3/4" angle to create the profile of a rain gutter for the roof rack feet to attach. Small blocks of 3/4" square stock are to support the 3/4" angle. Found a company to Power Coat the rails for around $50.00 also they did the frame for the cooler rack for $25.00.

It has worked out that the gap between the trailer bed and the car top box is a great place to put tent and folding chairs.

The trailer is rated for much heaver loads that I would use for motorcycle towing. To soften the trailer I removed some of the leafs from the springs. This seems to be working out fine.

Here are some pictures of my finished trailer.