eddieshep999

Active member

A friend of mine wanted to renew his roller on Doc Humphries Vibration Damper

Unfortunately Doc Humphries is no longer trading

He did see if he could fit Lamonster larger roller to it but was advised it wasn’t suitable

He has found a replacement and posted this on our UK Spyder Website Facebook page

As this information may be useful to others with Doc Humphries Vibration Damper he has given me permission to post the details here :-

DRIVE BEŁT ROLLER UPGRADE

For information of Paul Phillips and Duncan Parker.......Re Eddie Sheppard post last week regarding belt tensioner roller upgrade ...

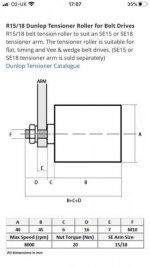

I have today fitted the Dunlop R15/18 larger roller to my Doc Humphries tensioner arm.

Had to drill out the 6mm hole to 10mm but the end result is a decent two bearing roller with larger diameter and good coverage of the belt.....well up to the job

Unfortunately Doc Humphries is no longer trading

He did see if he could fit Lamonster larger roller to it but was advised it wasn’t suitable

He has found a replacement and posted this on our UK Spyder Website Facebook page

As this information may be useful to others with Doc Humphries Vibration Damper he has given me permission to post the details here :-

DRIVE BEŁT ROLLER UPGRADE

For information of Paul Phillips and Duncan Parker.......Re Eddie Sheppard post last week regarding belt tensioner roller upgrade ...

I have today fitted the Dunlop R15/18 larger roller to my Doc Humphries tensioner arm.

Had to drill out the 6mm hole to 10mm but the end result is a decent two bearing roller with larger diameter and good coverage of the belt.....well up to the job