agedbikeman

New member

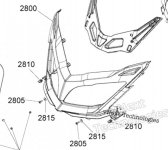

I need to remove the frunk to replace the LH headlight bulb (UK model)

There are 2 bolts underneath that hold the bottom of the frunk to the chassis, they screw into plastic encapsulated nuts The bolts are not stainless just plain steel, one of the bolts is rusted into the nut, now the nut is just turning in its plastic holder, how am I supposed to get this bolt undone as there is no way of holding the nut. They do the same nasty trick on the inside of the front fender supports.

I dont think derusting agents will help as you can't hold the nut with anything

Anyone else had this problem

Alex

There are 2 bolts underneath that hold the bottom of the frunk to the chassis, they screw into plastic encapsulated nuts The bolts are not stainless just plain steel, one of the bolts is rusted into the nut, now the nut is just turning in its plastic holder, how am I supposed to get this bolt undone as there is no way of holding the nut. They do the same nasty trick on the inside of the front fender supports.

I dont think derusting agents will help as you can't hold the nut with anything

Anyone else had this problem

Alex