Fromridgewood

New member

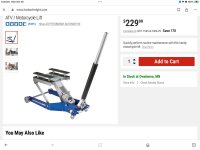

HELLO Everyone. I have a 2022 F3T. I like to periodically spin the rear tire and check for glass, nails, or any debris caught in the treads that I think may cause a flat tire on a long ride. Sometimes, what appears to be harmless road debris will puncture the tire after a few hundred miles. I can't get on my back anymore, so I like to sit on a shop roller chair and inspect the tire. The trouble is that I need to get the rear tire jacked up and off the ground in order to do my inspection. Anyone have the same habit; and if so, how do you jack up the rear tire on this bike? TIA.

Last edited by a moderator: