PMK

Active member

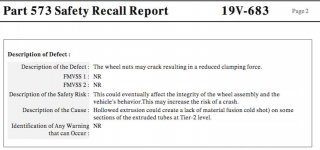

I'm no expert but I work in the engineering field. With the quality of simulation software engineers are able to test all sorts of parts/designs/ideas for various types of failures before the actual part is ever built. The software is expensive and BRP is running the Dassault Systems suite of tools. These are the same tools many aerospace companies use (boeing, Airbus, etc) to simulate designs. The software is very accurate. I'm not saying it never happens but typically, in today's world, if a failure takes place its a materials/manufacturing issue rather than a design issue. You can't completely release the engineer/designer from the hook because its possible they design something difficult to make and that leads to a materials/manufacturing issue but in general an experienced engineer would know if a design will fail long before its ever built.

CATIA is an excellent program. As mentioned when correctly used, it does offer an immense capability. I do agree also that it does very well at predicting time to failure or first failure location.

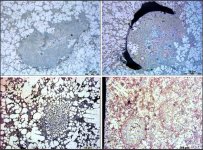

Without doubt, if the issue is identified as defective raw material, there is no means to predict anything more than replace the part.

Regarding what software or evaluation is utilized by BRP, the end result is the fastener failed. Defective material could happen in solid material or hollow material, so that is an interesting remark.

No doubt BRP will sort it out and restore confidence.