Late thought there were few managed to reverse the HCM filter & other problems filter related.

I ignored this comment because I didn't understand it but it is possible the dealer didn't replace the HCM oil filter when they changed the oil when I purchased it. I'll order a new one and replace it and see if that changes anything.

Several people have told me this. But the HCM uses oil pressure to shift the transmission. What it might do is shift into neutral after it starts. Today I shut the engine off while it was in reverse on purpose. It started but it didn't shift into neutral. It stayed in reverse.

That's exactly the way it works. Based on all that you have said and we discussed, it would be good to check the oil pressure.

Given what you've told us elsewhere about the way you check your oil, doing it before you ride and not waiting long enough until it's warm enough to get the level & volume right; and the fact that if the oil volume & pressure isn't pretty much

EXACTLY RIGHT on these V-Twin Spyders, the computers on them can/will just refuse to shift at all; and with what you tell us you've already checked and hopefully eliminated; all of the above suggests that you

may have an oil problem... pressure &/or volume - except that they do

usually show codes when that sort of problem happens, at least, they do if it happens while you're riding; so if you haven't been able to ride &/or run the engine for too long in the recent past, then maybe... :dontknow:

So your 'failure to shift' issues

could be oil pressure related, for any of number of reasons, including that possibly the HCM filter is the wrong one, &/or maybe it's inserted backwards, so that no oil pressure gets thru at all, but if the SE has changed gears when prompted by the flappy paddles

at all since your last oil & filter change, then it's

probably not that...

But you don't necessarily need a new filter to check that, you could do it now!! :lecturef_smilie:

Or

maybe running it with the incorrect volume of oil over a longish period (oil level/volume either too high when it's hot, or too low when it's hot; but you'll likely only see that if you do your oil level check

after much longer than it takes to get the radiator cooling system up to fan operating temps; saaay, by running it for

at least 30 mins of riding at Hwy revs/speeds with some gear changes up & down, etc.) due to using the incorrect checking process, means the lack/excess of oil volume could've damaged the scavenge &/or pressure pump/s; or possibly even just worn the seals; such that now the engine &/or trans is not getting suitable oil pressure/volume at the right time to even

think about doing anything like shifting ... :banghead:

Or maybe the LH Control Module (the Handgrip & selector) has just given up thru age & time or there's no signal getting thru to the TCM or HCM for some other reason... :dontknow:

My thoughts to proceed from where you are now would be to check the oil level properly, even if that means draining it all out and refilling with it

just the correct quantity if you can't do the checking process correctly within a couple of minutes

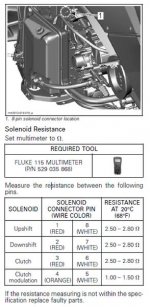

AFTERa ride; and checking the HCM filter by taking the cover off, removing it, and visually/physically ensuring it's relatively clean, the right length (there's a long & a short filter for these things, and some have put the short filter in the long housing - but your Spyder just won't change gear if you do that!!

) it'll probably be a tad less messy if the oil is drained when you do unscrew the cover... Oh, & IIRC, the 3 screws aren't all the same length, so you

MUST put them back in the correct holes! :sour:

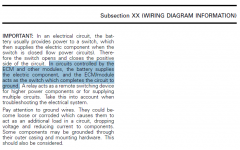

Only after doing all this ^^ would I start looking further afield - there's still things like wiring looms to check, connectors to ensure are properly connecting, and probably a bunch of other stuff you can do while you wait 'til you can get it to a dealer. Good Luck! :cheers: