Riding update 2.

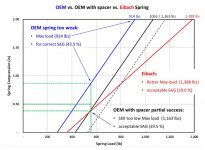

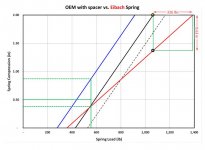

I did a little more riding when the ground was dry and was able to push the riding envelope a little bit. Based on the previous riding, I thought I would be seeing about 900 lbs on the front, but it looks like it is more like 1100 lbs. This means the original PVC preload spacer was not going to be thick enough.

I set out to make a thicker spacer, but decided not to make it all out of PVC; not because it will not work, but because my fellow RT riders may not try this as they desire a metal spacer. So, I made the spacer out of 1 1/5" galvanized pipe with a pvc outer sleeve (the pvc pipe is for cosmetic purposes as the metal is more than strong enough to support the loads it will see).

Pic 1 is what I brought home from Home depot. I went to the plumbing section and got the man there to cut two 1" spacers with their machine. I later checked them and found that they are slightly more than 1" (1.05").

Pic 2 is after I sanded the metal ends and cut one PVC outer sleeve, then pushed the metal spacer into the pvc spacer (nice snug fit), then sanded the pvc ends flush with the metal.

Pic 3 show both spacers complete

Pic 4 I cleaned the pvc outer to remove the bar code ink, then painted them black

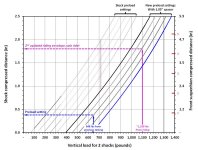

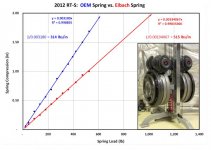

Pic 5 is the projected performance envelope. The initial sag is not where I'd like it to be, but I have to hedge on this side to preserve margin on the other end. It looks like for solo riding I'll use 15% (~0.38") of the 2.5" working range of the shock for the initial sag setting. 65% (1.62") of the shock will be used as I ride, and 20% (0.5") is my reserve. When I carry a passenger, I'll have to dial in my last 2 oem preload indents.

I'll use the ratchet technique to compress the spring this time as it really worked nicely on the rear spring. I'll post back how this all work and include a 3rd riding update.

Elka shocks are superior to be sure, but adding spacers gets the oem shock into a serviceable range and saves $$$'s for a corbin seat and possibly some floorboards. Plus, I will not be scraping the bottom of my frunk anymore. If you look at pic 5 on the right side, you will see I added the front suspension compression range. It is not exacly linear to the shock compression distance, but is very close to being a linear relationship, so I added it so you can see how low the front of the bike dips as the shock is compressed. For those of you that weigh over 200 and still ride on oem shocks (even with full preload), the bottom of your frunk is scrapping the asphalt some times.

Dan - if you are still interested, I can work up a patch of mixed metal and pvc spacers like mine (I'll pm you on what it would cost to include shipping). Of you can go down to HD to get the parts and do this yourself for about $15. After I get mine in, I'll be able to tell you what thickness you need to make them.

Jerry