spacetiger

New member

Jim has a separate thread going on with his suspension (http://www.spyderlovers.com/forums/showthread.php?60434-RT-Weight-distribution). Rather than gum up that thread, I'll post my activities (similar subject) here and link my efforts back to his.

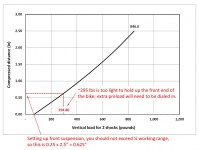

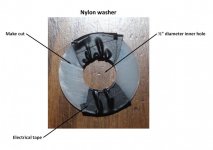

For me, I am gathering information to see how I want to modify my suspension (if any). I have already replaced the swaybar to a thicker (stiffer) one. It has done wonders to handle turns and keeping you flat. That leaves the shocks to be looked at. In this first posting, I am putting up the results of bench testing the front right shock to determine the K value of the front spring. Having removed the shock, I placed it in some gym equipment to allow me to add 45 and 35 lb plates, 1 at a time, while measuring how much the shock compresses. I was able to put 430 lbs on but found it was not sufficient to compress the shock. (Pic 1)

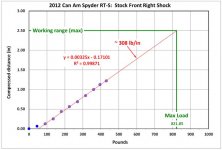

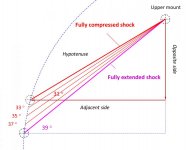

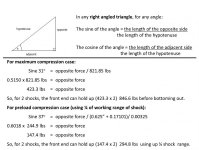

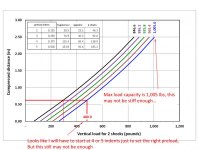

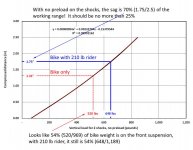

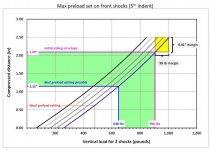

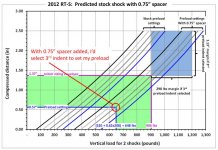

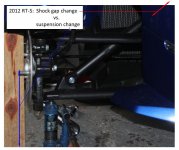

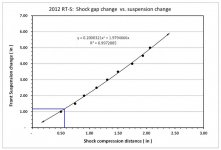

Based on the data, I can plot the data and use a linear curve fit to determine the spring rate (pic 3). It turned out to be just under 308 lbs/in. With a working range of 2.5 inches and a preload amount of 50 lbs, the max load per shock before bottoming out is ~821 lbs. So, with 2 shocks, it is 1642 lbs. But, the shock is mounted at an angle, so that has to be accounted for. I'll work that out later tonight.

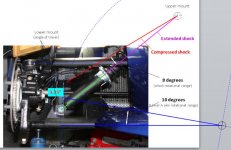

Basic shock info (pic 2):

ETE length (measured, inches): 17 11/16 or 17.688"

Working range (measured, inches): 2.50"

Jerry

For me, I am gathering information to see how I want to modify my suspension (if any). I have already replaced the swaybar to a thicker (stiffer) one. It has done wonders to handle turns and keeping you flat. That leaves the shocks to be looked at. In this first posting, I am putting up the results of bench testing the front right shock to determine the K value of the front spring. Having removed the shock, I placed it in some gym equipment to allow me to add 45 and 35 lb plates, 1 at a time, while measuring how much the shock compresses. I was able to put 430 lbs on but found it was not sufficient to compress the shock. (Pic 1)

Based on the data, I can plot the data and use a linear curve fit to determine the spring rate (pic 3). It turned out to be just under 308 lbs/in. With a working range of 2.5 inches and a preload amount of 50 lbs, the max load per shock before bottoming out is ~821 lbs. So, with 2 shocks, it is 1642 lbs. But, the shock is mounted at an angle, so that has to be accounted for. I'll work that out later tonight.

Basic shock info (pic 2):

ETE length (measured, inches): 17 11/16 or 17.688"

Working range (measured, inches): 2.50"

Jerry

Attachments

Last edited: