Recently changed the rear tire using Lamonsters method. That went well, but for some reason the alignment is no longer the same. I've tried to tweak it according to the service manual, but not getting the desired results. If I set the belt to have 1mm of space from the pulley, the belt walks pretty far off the pulley when the bike travels any distance in reverse. To keep the belt mostly on the pulley when reversed the belt is right up against the pulley. I've measured the distance on both sides of the axle and they are both the same distance from the back of the swing arm. What is the trick to getting this aligned properly?

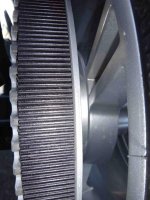

Belt location after riding forward.

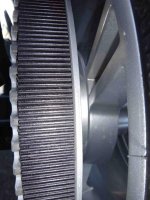

below location after riding backwards for a distance.

Belt location after riding forward.

below location after riding backwards for a distance.