mgardiner2673

New member

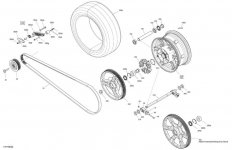

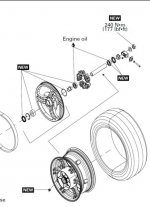

I have my new tire on, brake disk, and reluctor ring installed, but now I can't get the rear pulley to seat properly.

I have a new O-ring oiled, and ready to install the pulley. Pulley will not seat completely. I've even greased the cush rubbers slightly to better slide the pulley onto the wheel. Pulley will not seat past the O-ring. Any ideas why? Help will be greatly appreciated!

I have a new O-ring oiled, and ready to install the pulley. Pulley will not seat completely. I've even greased the cush rubbers slightly to better slide the pulley onto the wheel. Pulley will not seat past the O-ring. Any ideas why? Help will be greatly appreciated!

Last edited by a moderator: