Batmobil-F3

New member

You don't have to speculate. In the official Safety Recall Report, BRP describes the cause.

Extract from the report:

Chronology :

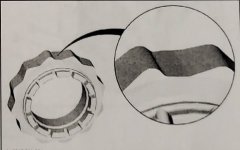

In July 2019, BRP started receiving reports of cracked wheel nuts. Each wheel has one nut. This assembly is

specific to our Ryker model which was introduced in MY2019.

BRP started its investigation and requested parts from the field. The pattern of reports accelerated in August.

The investigation included discussion with the suppliers to identify any possible deviation in the parts

manufacturing process. This part is made by a Tier 1 and a Tier 2. The issue was identified as coming from the

hollowed aluminum extrusion process of the Tier 2 supplier.

BRP performed tests to evaluate the possible impact on a vehicle of a cracked nut. Also, the investigation was

pointing on a possible reception of bad lot of parts sometimes during the production and not from the

beginning of the MY2019 production. Therefore, BRP started the process to identify and locate the lot.

As BRP’s investigation was ongoing, NHTSA contacted BRP during the week of August 19 regarding the wheel

assembly.

From that week up to the week of September 15, tests were completed and taking in consideration discussions

with NHSTA, BRP decided to issue a Safety Recall on the affected vehicles.

BRP received at least one bad lot of parts starting on February 7th and is unable to isolate the parts with

enough certainty up to the vehicles produced on September 13, 2019. This includes some MY2019 and 2020

vehicles.

No injuries were reported

As of September 18, 2019, BRP identified a total of 44 reports worldwide of cracked wheel nuts including 41 in

the United States. There are also 6 VOQs files at NHTSA and upon information we have (excerpt of VIN and

State) we beleive that they were alos part of the 41 reports

Extract from the report:

Chronology :

In July 2019, BRP started receiving reports of cracked wheel nuts. Each wheel has one nut. This assembly is

specific to our Ryker model which was introduced in MY2019.

BRP started its investigation and requested parts from the field. The pattern of reports accelerated in August.

The investigation included discussion with the suppliers to identify any possible deviation in the parts

manufacturing process. This part is made by a Tier 1 and a Tier 2. The issue was identified as coming from the

hollowed aluminum extrusion process of the Tier 2 supplier.

BRP performed tests to evaluate the possible impact on a vehicle of a cracked nut. Also, the investigation was

pointing on a possible reception of bad lot of parts sometimes during the production and not from the

beginning of the MY2019 production. Therefore, BRP started the process to identify and locate the lot.

As BRP’s investigation was ongoing, NHTSA contacted BRP during the week of August 19 regarding the wheel

assembly.

From that week up to the week of September 15, tests were completed and taking in consideration discussions

with NHSTA, BRP decided to issue a Safety Recall on the affected vehicles.

BRP received at least one bad lot of parts starting on February 7th and is unable to isolate the parts with

enough certainty up to the vehicles produced on September 13, 2019. This includes some MY2019 and 2020

vehicles.

No injuries were reported

As of September 18, 2019, BRP identified a total of 44 reports worldwide of cracked wheel nuts including 41 in

the United States. There are also 6 VOQs files at NHTSA and upon information we have (excerpt of VIN and

State) we beleive that they were alos part of the 41 reports