-

There were many reasons for the change of the site software, the biggest was security. The age of the old software also meant no server updates for certain programs. There are many benefits to the new software, one of the biggest is the mobile functionality. Ill fix up some stuff in the coming days, we'll also try to get some of the old addons back or the data imported back into the site like the garage. To create a thread or to reply with a post is basically the same as it was in the prior software. The default style of the site is light colored, but i temporarily added a darker colored style, to change you can find a link at the bottom of the site.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheels falling off?

- Thread starter WilliamTRyker

- Start date

IdahoMtnSpyder

Well-known member

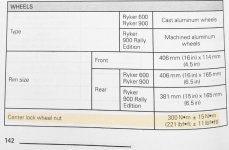

I just got to wondering. No one has said anything about holding the wheel so it doesn't rotate while torquing the nut. How do you guys do that, or plan to do it? I'm sure the weight of the Ryker isn't going to be enough to simply rely on tire to floor friction to hold it against 221 lb-ft of turning torque. I sometimes turn the tire on the Spyder breaking the lug nuts loose!

BajaRon

Well-known member

I'm not talking about riding around with a breaker bar, but the socket itself would be great in and when the event happens where you get a flat and a broken bead bombing around on back country two track with the closest Bombi dealer being 200 miles away, with the socket you can get to any Joe's Garage and get your tire repaired.

BRP is advertisng the machine as an offroad vehicle and at the very least IMO BRP should provide or at least offer the socket at a reasonable price for the offroad rider, I know if it was me riding a Ryker offroad I would have the socket just to avoid a blown day driving to a Can Am dealer :cheers:

https://www.youtube.com/watch?v=3w0gKBvXZgs

You don't see any true off-roading in this video. As mentioned before. BRP calls the Ryker Rally an 'Off Pavement' vehicle. Everything in that video is an improved road surface or equivalent. I highly recommend not using any Ryker as a true off road vehicle. I think you are going to be quite disappointed, and probably out a good deal of money in repairs if you do.

If you are worried about flats, use Ride-On or similar. There are so many myths and wives tales about tire sealant/balancers it's hard to get past the smoke sometimes. But I use Ride-On and I like it. Could easily save you from getting stranded or paying a tow bill. And even if you never need it to seal, you'll still have the balancing affects.

So don't buy your 65mm socket from BRP. Get this one for about $28.60 on eBay. https://www.ebay.com/itm/CT4013-65m...014177&hash=item1cbec0a6c1:g:lpoAAOSwoZlb2C5F

That's what I did. Works great! For about $10.00 more you can get one shipped from a US based vendor if you want it quicker. A decent torque wrench will cost you a bit more. And, if you get a 1/2 drive torque wrench you'll also need one of these. https://www.ebay.com/itm/1-2-Female...081431?hash=item23b052f297:g:oF4AAOSwpLxcdpKF

When I and others mentioned a 250 lb. ft. torque wrench, it was not because the wheel nuts on the Ryker require this amount of torque. But because to get to 211 lb. ft. torque you will need at least a 250 lb. ft. torque wrench. A torque wrench tends to be less accurate at the lower and upper limits of their capabilities. But being about 30 lbs. away from the upper limit, a 250 lb. ft. wrench is going to be quite accurate enough, as long as you get a decent tool and you don't abuse it.

Last edited:

Tslepebull

Active member

I have had my 65 mm socket for some time but it occurred to me that it is much more likely that the shop on the road will have a 1/2 drive torque wrench than 3/4. Therefore I had just ordered the 3/4 to 1/2 inch adapter when I saw your post. Timely

BajaRon

Well-known member

I have had my 65 mm socket for some time but it occurred to me that it is much more likely that the shop on the road will have a 1/2 drive torque wrench than 3/4. Therefore I had just ordered the 3/4 to 1/2 inch adapter when I saw your post. Timely

Now that you can definitely carry on your Ryker!

That 65mm socket from FleaBay may work but it is definitely not the correct one. If I'm torquing to 215 ft. lbs I definitely want the correct socket. I do think BRP should supply this no charge because no one but a Can Am Dealer will have one if you need a flat fixed. I guess I will bite the bullet and buy one when I pick up my Rally.

jcthorne

Well-known member

That 65mm socket from FleaBay may work but it is definitely not the correct one. If I'm torquing to 215 ft. lbs I definitely want the correct socket. I do think BRP should supply this no charge because no one but a Can Am Dealer will have one if you need a flat fixed. I guess I will bite the bullet and buy one when I pick up my Rally.

Why do you feel the 65mm socket (normally used on some Ford Transit Connect vans) is the incorrect one? There are a wide range of quality in tools but there are some well made ones available. 65mm 12 point socket is a universal size. There is nothing special about the one from BRP other than its from OEM Tool and marked up several times as it passes through the supply chain. Its a quality socket but nothing special.

BajaRon

Well-known member

That 65mm socket from FleaBay may work but it is definitely not the correct one. If I'm torquing to 215 ft. lbs I definitely want the correct socket. I do think BRP should supply this no charge because no one but a Can Am Dealer will have one if you need a flat fixed. I guess I will bite the bullet and buy one when I pick up my Rally.

I have removed and torqued a wheel nut with this socket. It is not of the finest quality, but it works perfectly. Not sure how the BRP socket will do any better. I did use a thin piece of plastic over the nut to protect it. But I would recommend doing this with any socket you choose. 211 lb. ft. of torque is bound to leave a mark if you don't.

Tslepebull

Active member

If I was a dealer technician and was going to be working on Rykers every day I would probably buy the BRP socket. But to me the Ebay 65 mm socket and 1/2 to 3/4 adapter will be stashed on the bike and were purchased as "get home" quaity items. That being said I will test them in the garage before I venture out so that I do not have a false sense of security.

Tslepebull

Active member

Poli, I'm not sure if you have tackled the rear wheel yet but it appears the socket will need an extension so that the torque wrench clears the tire. I ordered one of these: https://www.amazon.com/gp/product/B000FP8C78/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1. Not so much with the breaker bar because it can be angled away from the tire. And I have to admit to being a bit of a tool wh..e

Why do you feel the 65mm socket (normally used on some Ford Transit Connect vans) is the incorrect one? There are a wide range of quality in tools but there are some well made ones available. 65mm 12 point socket is a universal size. There is nothing special about the one from BRP other than its from OEM Tool and marked up several times as it passes through the supply chain. Its a quality socket but nothing special.

Because the one on Fleabay isn't even shaped properly to fit the nut, that's why I think it is incorrect. The one on Fleabay is rounded where the BRP tool is more straight cut and a star pattern. Use what you want. all I'm saying is it isn't the correct one.

poli

New member

Poli, I'm not sure if you have tackled the rear wheel yet but it appears the socket will need an extension so that the torque wrench clears the tire. I ordered one of these: https://www.amazon.com/gp/product/B000FP8C78/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1. Not so much with the breaker bar because it can be angled away from the tire. And I have to admit to being a bit of a tool wh..e

I've checked torque on rear wheel. I have a 1/2" torque wrench and with the 1/2 to 3/4 adapter, it works without any extension.

jcthorne

Well-known member

Because the one on Fleabay isn't even shaped properly to fit the nut, that's why I think it is incorrect. The one on Fleabay is rounded where the BRP tool is more straight cut and a star pattern. Use what you want. all I'm saying is it isn't the correct one.

Then we are looking at different sockets. It should be a standard straight cut 12 point 65mm socket. Not rounded. But there are plenty of them out there for less than $50. I have one from 'tru-craft' Its not Snap on quality but its fine. Its not rounded.

Tslepebull

Active member

I've checked torque on rear wheel. I have a 1/2" torque wrench and with the 1/2 to 3/4 adapter, it works without any extension.

Good information. I could not find anything n 3/4 inch drive less than 4 inches in length. I bit the bullet and purchases a 3/4 inch drive breaker bar and torque wrench that goes up to 350 ft pounds. Did I mention that I was a tool Wh..e?

BajaRon

Well-known member

Because the one on Fleabay isn't even shaped properly to fit the nut, that's why I think it is incorrect. The one on Fleabay is rounded where the BRP tool is more straight cut and a star pattern. Use what you want. all I'm saying is it isn't the correct one.

The picture is misleading. I am not sure if it is the angle or what. But the socket I received is the standard, straight cut socket. The same one you'll get if you pay more, to a point.

IdahoMtnSpyder

Well-known member

OK guys, this is what you need! After much searching I finally find the ideal unit, a torque multiplier. This unit has a 3.4 to 1 torque ratio with 1/2" drive in and out. Get the nut snugged down, then put the socket on the output drive, your torque wrench on the input side, rest the torque arm on something secure, and tighten away. You can easily put 220 lbf-ft of torque on the nut using only 65 lbf-ft of torque on your wrench. You might even be able to carry the socket, this multiplier, and a 1/2" torque wrench on the Ryker somewhere.

https://www.northerntool.com/shop/tools/product_200712282_200712282

https://www.northerntool.com/shop/tools/product_200712282_200712282

Warlock

New member

OK guys, this is what you need! After much searching I finally find the ideal unit, a torque multiplier. This unit has a 3.4 to 1 torque ratio with 1/2" drive in and out. Get the nut snugged down, then put the socket on the output drive, your torque wrench on the input side, rest the torque arm on something secure, and tighten away. You can easily put 220 lbf-ft of torque on the nut using only 65 lbf-ft of torque on your wrench. You might even be able to carry the socket, this multiplier, and a 1/2" torque wrench on the Ryker somewhere.

https://www.northerntool.com/shop/tools/product_200712282_200712282

View attachment 171231

I use to use a much bigger version of a torque multiplier on rig equipment. Some of our bolts require close to 1000 ft lbs and these things are a life saver.

David

Similar threads

- Replies

- 13

- Views

- 5K

- Replies

- 2

- Views

- 3K

- Replies

- 193

- Views

- 70K