IdahoMtnSpyder

Well-known member

All I found was some other links regarding reducing torque for wet or oiled fittings. They suggest reducing the spec dry torque by 10-25% depending on source. They also note that torque should not be reduced if Loctite or similar is applied, but it just doesn't feel right:bowdown:

:dontknow:

http://raskcycle.com/techtip/webdoc14.html

http://www.antiseize.com/pdf/torque_specifications.pdf

Here's a page with a diagram showing the components of the torque in tightening nuts and bolts. A small change in turning friction can cause a huge change in the stretching component, which can have a tremendous impact on the tightness and safety of the bolt.

http://www.boltscience.com/pages/tighten.htm

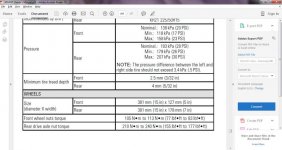

The chart here shows how the recommended torque varies widely based on the strength of the steel in the fastener.

http://www.portlandbolt.com/technical/bolt-torque-chart/

These variables show why it is important to pay attention to the manual specifications. It's easy to over torque or under torque a fastener. Put too great a torque on soft steel you'll have failure. Put insufficient torque on high strength steel fastener and you can have a failure.