pitzerwm

New member

I bought it used a month or so ago and while its been crappy weather, I did get enough riding in to pass the state driving test.

I added the BajaRon's anti sway bar and the links, by taking off the frunk, a piece of cake. These are the videos that helped most. http://www.spyderlovers.com/forums/...-Anti-Sway-Bar-install&highlight=BajaRon+Sway

I added 3 power plugs, 2 in the frunk and one on the side. Needed a radar det. so used a Rom X-grip and another one for the GPS or phone. I wired them hot with a switch on the dash

The blue screwdriver on the handlebar is my answer to get the cluster out without removing the windshield.

Added speakers to my helmet that connect to my bluetooth on the phone or the GPS.

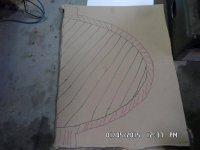

Waiting for an actuator to electrify the frunk. And waiting for the LEDs to be seen easier. Ordered the HDPE stuff to make a bump plate, will post pixs if that works out.

I added the BajaRon's anti sway bar and the links, by taking off the frunk, a piece of cake. These are the videos that helped most. http://www.spyderlovers.com/forums/...-Anti-Sway-Bar-install&highlight=BajaRon+Sway

I added 3 power plugs, 2 in the frunk and one on the side. Needed a radar det. so used a Rom X-grip and another one for the GPS or phone. I wired them hot with a switch on the dash

The blue screwdriver on the handlebar is my answer to get the cluster out without removing the windshield.

Added speakers to my helmet that connect to my bluetooth on the phone or the GPS.

Waiting for an actuator to electrify the frunk. And waiting for the LEDs to be seen easier. Ordered the HDPE stuff to make a bump plate, will post pixs if that works out.

Attachments

Last edited: