Goal:

To entertain myself and learn more about the system. I don't think it would be very hard (but probably expensive) to duplicate what I can do with my OBDII adapter on my car.

I have some pie in the sky dreams to bring BUDS to the masses but I don't know if it is technically possible or legal. In all seriousness, is anyone here a real lawyer with knowledge of IP law? Contact me off the forum.

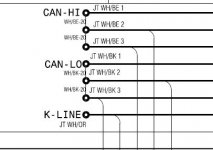

CAN is not an extremely complex protocol to listen to the bus. What is hard is talking on the bus and correctly handling the data collisions when you try to talk at the same time as someone else. But for now, I just hope to listen to the bus.

I highly doubt there is any form of encryption for most of the system data. Encryption adds processing overhead on both the sender and the receiver which drives up cost for the processor and/or makes them run slower and/or makes them burn more power. A lot of downside for very little benefit.

That said, most of the "good stuff" is probably difficult to figure out. I seriously doubt that I will be able to (or even want to) mess with VSS or the "nanny". But it should be easy to get access to all the stuff on your displays from the CAN bus (RPM, coolant temp, gear, speed, etc).

I've got a microcontroller with CAN on order.

By the way, I plan on open sourcing all my work if I get anything remotely interesting. I might sell kits or services but I'll share what I learn.

My main motivation for this is the lack of control of my vehicle and being forced to rely on the dealer. I took my spyder in for an error code to the dealer on Saturday (

http://www.spyderlovers.com/forums/showthread.php?42446-Brake-Failure-Code-1282-on-08-GS-need-advice). When I called on Tuesday for status, they had already ordered the parts for a warranty replacement of the calipers. It may be petty, but I want to be able to analyze my own systems and decide what is wrong. My chosen dealer seems to be pretty smart and honest but I still trust my own judgment more than anyone else's.

I want the tools and knowledge to be able to analyze what's wrong with my vehicle before I have to drive 45 minutes away with another driver to pick me up.

So for now, baby steps. Connect a microcontroller with a CAN transceiver to the bus and listen to data. See if I can read the gear indicator data. We'll see where it leads.

By the way if someone has knowledge / skills with this stuff, I did buy a second connector if you want to help.

Anyone at BRP who anonymously sends me a protocol document would remain anonymous forever and I would never mention where all information came from.

ray:

It's a control thing... If your Spyder came with custom nuts and bolts that no standard tools could turn, owners would pitch a fit if they were prevented from doing basic maintenance. This thing is so heavily computerized that they have basically done the electronic equivalent of that. Read access to all the ECU codes should be a basic right of ownership. You should be allowed to know what the vehicle thinks is wrong.

What a diatribe... I was planning on keeping this low key but all the questions got me up on my soapbox.

David