ofdave

New member

:clap:.......do you happen to have the item , number for that ......Thanks ...Mike :thumbup:

sending you a PM with link

:clap:.......do you happen to have the item , number for that ......Thanks ...Mike :thumbup:

:agree: ............ and let me add that you can easily make the Paint tougher by putting it a 275 degree oven and letting it bake for 10 minutes after it has thoroughly Dried ..... If you do it sooner it will smell....After the volatiles have dried it bakes with only a minor smell ...... I just did my re-painted car wheels ...... Mike :thumbup: ......PS do not do this on PlasticPainting The Modified Brackets

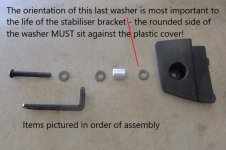

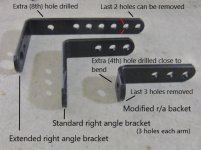

Please ensure that any raised edges on the holes or where brackets have been cut, are removed, to ensure a strong fit to the adjacent bracket or bolt.

Place the brackets on their edge.

Spray 3 or 4 light coats from about 12" away.

A light coat is one which still looks dull and dry. A heavy coat is one which looks wet and thick, and runs. It will take a day to dry properly.

Don't try to cover all the bare metal with the first coat - the paint should be touch dry in 60 seconds to allow you to turn the brackets over on their other edge.

Turn the brackets around, as well, so that you are painting from the opposite side or angle.

Multiple light coats at one or two minute intervals will produce good cover which will be touch dry in minutes, and usable in about half an hour.