tehrlich

New member

I installed a set of Fox Shocks on my RT Limited tonight, and I think it is a HUGE improvement! I could feel the difference on the VERY first turn I took! (I'm installing the upgraded swaybar later. but this was a major improvement in my opinion)

I will admit that I was concerned about doing it myself, but it was very easy. It took me about 45 minutes, but it was hot in my garage, and I took my time. This is the very first time for me to do this, and I found it so easy that I took pictures during the 2nd install. Please be advised that I'm an amateur and am showing the pictures only to show how easy it is, and what I discovered.

It was surprising to me that the stock shock seemed to have the same size spring and piston. It was also heavier.

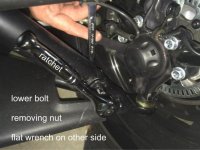

I only used a few things: a 15mm wrench, a 15mm ratchet, and a low-profile hydraulic jack.

I had to elevate the front just a little to get the hydraulic jack to go under.

I removed the nut off of the upper bolt first. The tension of the shock on the bolt made it easy to get the nut loosened.

The room is very limited with hoses in the way. The backside of the shock is easy, and the front side of the shock has limited access to the bolt head. I found that if I slipped the flat wrench around the shock on the inside, I could get my hand around the outside of the shock to meet it over the bolt head. Just keeping the wrench on the bolt head is enough to get the nut off completely.

I will admit that I was concerned about doing it myself, but it was very easy. It took me about 45 minutes, but it was hot in my garage, and I took my time. This is the very first time for me to do this, and I found it so easy that I took pictures during the 2nd install. Please be advised that I'm an amateur and am showing the pictures only to show how easy it is, and what I discovered.

It was surprising to me that the stock shock seemed to have the same size spring and piston. It was also heavier.

I only used a few things: a 15mm wrench, a 15mm ratchet, and a low-profile hydraulic jack.

I had to elevate the front just a little to get the hydraulic jack to go under.

I removed the nut off of the upper bolt first. The tension of the shock on the bolt made it easy to get the nut loosened.

The room is very limited with hoses in the way. The backside of the shock is easy, and the front side of the shock has limited access to the bolt head. I found that if I slipped the flat wrench around the shock on the inside, I could get my hand around the outside of the shock to meet it over the bolt head. Just keeping the wrench on the bolt head is enough to get the nut off completely.