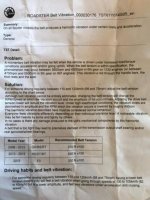

I have been reading some of the threads on this forum about belt tension and decided that I ought to know how to use a Krikit II V-Belt Tension Gauge (Part# 91132). For about $30 off Amazon, I acquired one and used it for the first time after reading the instructions that came with the gauge.

I took off the belt guard on my 2015 F3-S, found the midpoint on the top of the belt and then proceeded to take several readings of my belt's tension. The gauge read about 195-200 pounds. The trike has 7300 miles on it and I bought it as a factory demonstrator with 6k miles. At the time of pickup, the dealer had gone through the trike and did a complete service minus an alignment. They said that the alignment was fine. They had put all brand-new tires on it at my request as part of the sale and I have not noticed any unusual wear in the 1300 miles I have put on the trike and there is no tendency to pull one way or the other when hands free. I have experience very little belt vibration that occurs somewhere around 70-75 mph and seems slightly more pronounced when going up an incline.

My question is that now that I have established a baseline of 195-200 pounds on the Krikit, is this pretty much an ideal belt tension? In my readings, I have heard all kinds of numbers bandied about and can't really get a good handle on what is an ideal belt tension? Thanks for any insights. Bob

I took off the belt guard on my 2015 F3-S, found the midpoint on the top of the belt and then proceeded to take several readings of my belt's tension. The gauge read about 195-200 pounds. The trike has 7300 miles on it and I bought it as a factory demonstrator with 6k miles. At the time of pickup, the dealer had gone through the trike and did a complete service minus an alignment. They said that the alignment was fine. They had put all brand-new tires on it at my request as part of the sale and I have not noticed any unusual wear in the 1300 miles I have put on the trike and there is no tendency to pull one way or the other when hands free. I have experience very little belt vibration that occurs somewhere around 70-75 mph and seems slightly more pronounced when going up an incline.

My question is that now that I have established a baseline of 195-200 pounds on the Krikit, is this pretty much an ideal belt tension? In my readings, I have heard all kinds of numbers bandied about and can't really get a good handle on what is an ideal belt tension? Thanks for any insights. Bob

Last edited: