fatenhappy

New member

Seems like there has been millions of things happening during the passed few months, so the Spyder's mods have been on the back burner ?

Finally just this week, I thought I'd strike a blow as the custom wheels have been sitting in the garage for about 2 or 3 months or so. I really wanted to set up the basic platform so I can move on with Cathy's the side car project.

Part 1 went really well a while back in that the 3 to 5 stud wheel adapters worked out fantastically.

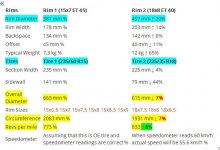

The real problem is I did not count on the F3's computer being quite so finitely calibrated with the differential between the front and rear wheels in their 'turns ratio' which is fed for such things as ABS, Anti-Skid etc.

For the uninitiated, the Can Am Spyders have different sized wheels (finished diameter after their respective tyres are fitted up - as standard) front and back. However the onboard computer has been precisely calibrated for that differential. So what you may say! Simply put as I found out the hard way if you are going to mess about with different diameter wheels the original front to back differential ratio has to be maintained.

So after all that, this is the way things have finally finished up just as of this afternoon. Jobs done ... 18x8s on the front ... but I had to go up two profile sizes from a 50 to 60 profile for the rear plus increase the width from a 225mm to a 235mm (which also added to the tyre diameter by 1/2".... which made all the difference.

Maths reworked and done, application applied and I am wrapped ... Everything is perfect with now only the replacement front mudguards to be further customised for their new 'special fit' ?

So finally, next comes Cathy's side car project ?

The new rear wheel tolerances were pretty tight, but with a rear wheel re-centering also done etc, in the end everything has worked out really well ?

Nanny's happy, I'm happy ? The only down side is with the speedo now under reading by about 3 kilometres per hour, but that is not a problem either as such as I ride using my GPS ? sweet !

Finally just this week, I thought I'd strike a blow as the custom wheels have been sitting in the garage for about 2 or 3 months or so. I really wanted to set up the basic platform so I can move on with Cathy's the side car project.

Part 1 went really well a while back in that the 3 to 5 stud wheel adapters worked out fantastically.

The real problem is I did not count on the F3's computer being quite so finitely calibrated with the differential between the front and rear wheels in their 'turns ratio' which is fed for such things as ABS, Anti-Skid etc.

For the uninitiated, the Can Am Spyders have different sized wheels (finished diameter after their respective tyres are fitted up - as standard) front and back. However the onboard computer has been precisely calibrated for that differential. So what you may say! Simply put as I found out the hard way if you are going to mess about with different diameter wheels the original front to back differential ratio has to be maintained.

So after all that, this is the way things have finally finished up just as of this afternoon. Jobs done ... 18x8s on the front ... but I had to go up two profile sizes from a 50 to 60 profile for the rear plus increase the width from a 225mm to a 235mm (which also added to the tyre diameter by 1/2".... which made all the difference.

Maths reworked and done, application applied and I am wrapped ... Everything is perfect with now only the replacement front mudguards to be further customised for their new 'special fit' ?

So finally, next comes Cathy's side car project ?

The new rear wheel tolerances were pretty tight, but with a rear wheel re-centering also done etc, in the end everything has worked out really well ?

Nanny's happy, I'm happy ? The only down side is with the speedo now under reading by about 3 kilometres per hour, but that is not a problem either as such as I ride using my GPS ? sweet !

Attachments

Last edited: