Snowbelt Spyder

Well-known member

Just thought I would put this out there in a new post rather than tack onto the other one. Lately we have seen some reports about vibration dampener roller failures and possible replacements for Doc’s roller. There has been some replacement rollers suggested, and fortunately the spec sheets are available, which show that the maximum rated roller speed is 8000 RPM. Sounds high, but I started to wonder just what that means in real life operation of the Spyder. Others have as well. Turns out, I don’t think it’s high enough.

So, with nothing better to do today, I set out with my calculator and measuring tools in order to equate roller RPM to ground speed. We’ll work with English units, ( you folks across the pond can convert it ) and all of the measurements were taken from my machine - a 998 RT with the ribbed belt.

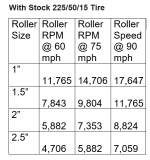

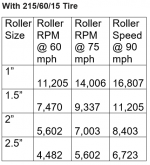

The roller being suggested has a diameter of 1.57”. That gives us a roller circumference of 4.9”. Next, we need to find out how many revolutions of the roller occur for one revolution of the drive belt. By direct measurement, my drive belt’s circumference is 112”. Thus, for each one revolution of the drive belt, the roller makes 22.9 revolutions. In that same single revolution of the drive belt, the Spyder moves forward 15.25’ (give or take a tenth) So, we now know that the roller makes 22.9 revolutions every 15.25 feet of bike travel.

So, how many revolutions does the roller make in a mile? We can set up our ratio now. In one mile, the drive belt makes 346.2 revolutions, and the roller makes 7928 revolutions. And of course, if we ride that mile in a minute - which is a speed of 60 MPH, then the roller is spinning at 7,928 RPM. Only a smidge below the 8000 maximum. In other words, that roller essentially reaches its maximum rated RPM when traveling at 60 MPH.

I don’t personally know what the rated RPM is on the bearings that Doc uses, or those that Lamonster uses. Both of these rollers have been seen to fail catastrophically. Doc’s roller is even smaller in diameter, closer to 1.25” - which will make it spin even faster. If his bearings are rated at the same 8000 RPM, then the ground speed to reach that number is even lower.

Looking at a hypothetical 2” roller, and doing all of the same math, it will be spinning at a rate of 6162 RPM at 60 MPH. If it has the same 8000 RPM bearings, that max will be reached at 77.9 MPH.

Bottom line is that a replacement roller for Docs arm, doesn’t only have to fit properly or have two bearings instead of one. It also has to have bearings with a sufficient RPM rating to handle the required vehicle speeds. That’s what we should be looking for. In the case of the rollers suggested, and perhaps Doc’s original one, they do not. I was surprised. Explains a lot. Feel free to double check my math or do your own.

So, with nothing better to do today, I set out with my calculator and measuring tools in order to equate roller RPM to ground speed. We’ll work with English units, ( you folks across the pond can convert it ) and all of the measurements were taken from my machine - a 998 RT with the ribbed belt.

The roller being suggested has a diameter of 1.57”. That gives us a roller circumference of 4.9”. Next, we need to find out how many revolutions of the roller occur for one revolution of the drive belt. By direct measurement, my drive belt’s circumference is 112”. Thus, for each one revolution of the drive belt, the roller makes 22.9 revolutions. In that same single revolution of the drive belt, the Spyder moves forward 15.25’ (give or take a tenth) So, we now know that the roller makes 22.9 revolutions every 15.25 feet of bike travel.

So, how many revolutions does the roller make in a mile? We can set up our ratio now. In one mile, the drive belt makes 346.2 revolutions, and the roller makes 7928 revolutions. And of course, if we ride that mile in a minute - which is a speed of 60 MPH, then the roller is spinning at 7,928 RPM. Only a smidge below the 8000 maximum. In other words, that roller essentially reaches its maximum rated RPM when traveling at 60 MPH.

I don’t personally know what the rated RPM is on the bearings that Doc uses, or those that Lamonster uses. Both of these rollers have been seen to fail catastrophically. Doc’s roller is even smaller in diameter, closer to 1.25” - which will make it spin even faster. If his bearings are rated at the same 8000 RPM, then the ground speed to reach that number is even lower.

Looking at a hypothetical 2” roller, and doing all of the same math, it will be spinning at a rate of 6162 RPM at 60 MPH. If it has the same 8000 RPM bearings, that max will be reached at 77.9 MPH.

Bottom line is that a replacement roller for Docs arm, doesn’t only have to fit properly or have two bearings instead of one. It also has to have bearings with a sufficient RPM rating to handle the required vehicle speeds. That’s what we should be looking for. In the case of the rollers suggested, and perhaps Doc’s original one, they do not. I was surprised. Explains a lot. Feel free to double check my math or do your own.