Hey guys/gals, We finally got around to joining the Spyderlovers after releasing our turbo kit to the market. Big thanks to Lamont helping us sponsor the forums.

Our History:

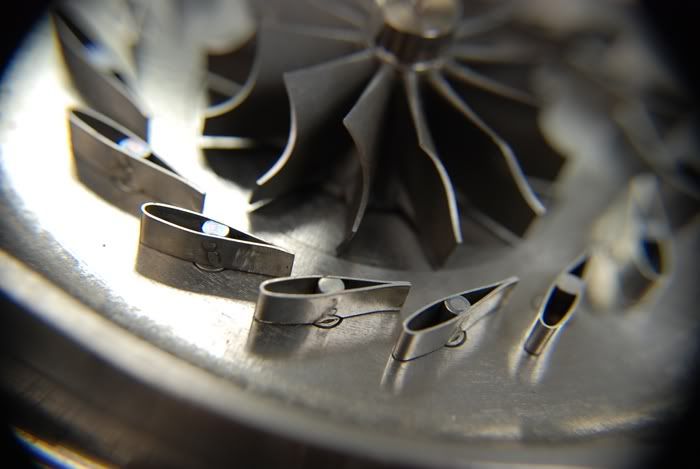

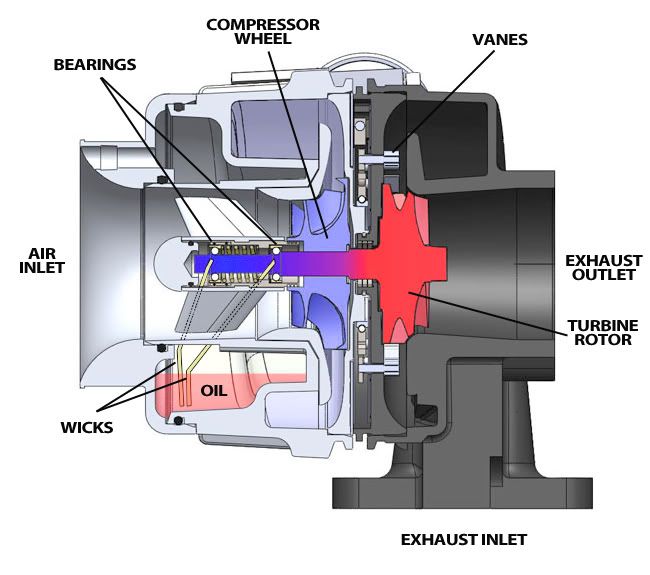

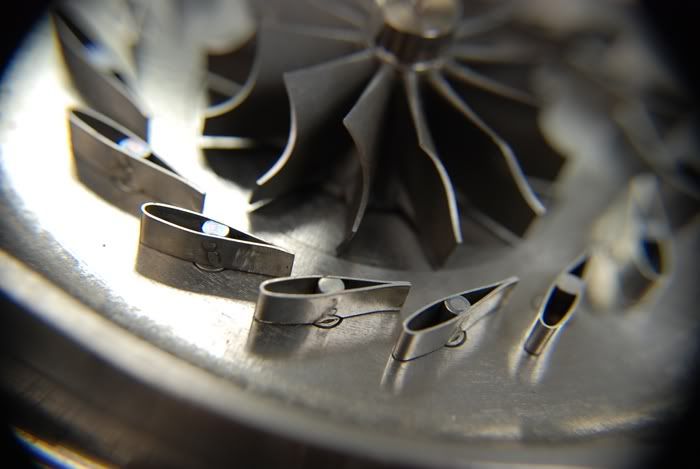

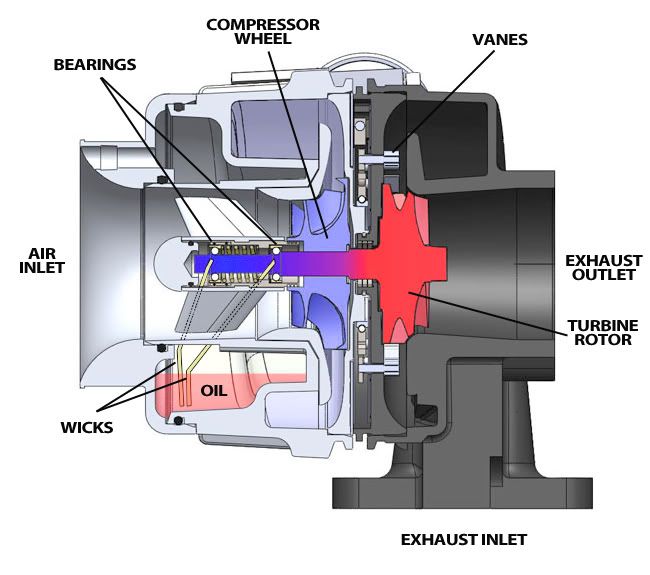

In 1976 our turbomachinery engineers wanted to improve on the design of conventional turbochargers and eliminate turbo lag from the equation. The end result was the Aerocharger which utilizes exhaust gases in the most efficient way possible to build boost instantly. This was achieved through a Variable Area Turbine Nozzle (VATN) design for the turbine section. VATN is a series of variable-vanes that optimize the flow area of the turbine by adapting to the exhaust gases. By doing this, the turbine wheel is able to operate at peak efficiency throughout a wide RPM range, something that has never been achieved before.

A unique self-contained oil system was also created for the Aerocharger which lubricates the ball bearings in a fine mist of oil. Since the oiling system is separate from the engine, a proper lubricant can be used for the precision ball bearings instead of using oil formulated for engines. This differs from conventional turbochargers that use a flooded bearing system which rely upon the engine’s lubrication system. By avoiding the use of a flooded design a virtually frictionless, self-contained bearing lubrication system was achieved.

Low rolling resistance coupled with a low-mass rotating assembly and VATN technology is why turbo-lag is virtually non-existent with the Aerocharger®. This also eliminates the need for a turbo timer as the bearings are low drag and hot oil cannot cook the bearings like conventional turbos. Therefore hot shut-downs are not longer and issue and a turbo timer is another component you will not have a need to purchase. A further advantage of this self-contained lubrication system is the fact that the turbo is no longer reliant upon being lubricated by the engine itself. There are no high pressure or lines or seals to fail and reduced oil leakage into the engine for low particulate emissions. This also allows for more mounting options to be available for the turbo including both horizontal and vertical installations

More info can be found here: ----------Aerocharger Technology Page----------

Enough about us, moving on to our Spyder turbo kit. At first we didn’t think there would be a big enough market to justify us building a kit for these bikes. But after seeing the cult following these bike have created, we couldn’t help but get involved. We certainly like the bold design of these bikes, but even more so we like the design of the exhaust which makes it perfect for a turbo conversion.

We decided to maintain the factory double-wall header pipes for heat management and ease of installation. With that out custom ceramic-coated down-pipe slides right into the factory location, which puts the turbo where the base of the factory muffler would be. Exiting out the turbo is our ceramic-coated muffler section. Already bought a custom exhaust for your Spyder? Chances are you can have a local exhaust shop cut and weld it onto our system if you like. Otherwise you can enjoy our stealth black muffler, which is arguably the best sounding exhaust for the Spyder.

Up front we have our custom air box and blow-off valve assembly. All designed for the best throttle response and drivability. You can also see the Aero-Commander fuel control box here. The Aero-Commander comes pre-tune with a fuel map but also allows for fine-tuning and on-the-fly adjustments to ensure you get your Spyder dialed-in to your specific riding style, elevation, local fuel quality, etc.

All of our intake side components are black powder-coated aluminum. Our air boxes & intercoolers are TIG welded in-house and all pipes are bead-rolled for a snug & secure fit.

All of our exhaust side components are satin black ceramic-coated for the best heat management and a stealth look. Even our turbos are black ceramic coated.

On top we have an AEM’s digital wide-band oxygen sensor gauge displaying your air/fuel ratio in real-time with both a digital and “analog” output in one gauge. Opposite the AEM is a VDO 0-15psi boost gauge to let you know when to hold on tight.

All in all this is one of our favorite kits. It’s a clean package with great results. You can expect 130-140wp with ease at 6psi with plenty of room to grow. We can also cater to those who have custom motor builds and may need a bigger turbo. Just give us a call and we can get a turbo matched to your engine.

Our History:

In 1976 our turbomachinery engineers wanted to improve on the design of conventional turbochargers and eliminate turbo lag from the equation. The end result was the Aerocharger which utilizes exhaust gases in the most efficient way possible to build boost instantly. This was achieved through a Variable Area Turbine Nozzle (VATN) design for the turbine section. VATN is a series of variable-vanes that optimize the flow area of the turbine by adapting to the exhaust gases. By doing this, the turbine wheel is able to operate at peak efficiency throughout a wide RPM range, something that has never been achieved before.

A unique self-contained oil system was also created for the Aerocharger which lubricates the ball bearings in a fine mist of oil. Since the oiling system is separate from the engine, a proper lubricant can be used for the precision ball bearings instead of using oil formulated for engines. This differs from conventional turbochargers that use a flooded bearing system which rely upon the engine’s lubrication system. By avoiding the use of a flooded design a virtually frictionless, self-contained bearing lubrication system was achieved.

Low rolling resistance coupled with a low-mass rotating assembly and VATN technology is why turbo-lag is virtually non-existent with the Aerocharger®. This also eliminates the need for a turbo timer as the bearings are low drag and hot oil cannot cook the bearings like conventional turbos. Therefore hot shut-downs are not longer and issue and a turbo timer is another component you will not have a need to purchase. A further advantage of this self-contained lubrication system is the fact that the turbo is no longer reliant upon being lubricated by the engine itself. There are no high pressure or lines or seals to fail and reduced oil leakage into the engine for low particulate emissions. This also allows for more mounting options to be available for the turbo including both horizontal and vertical installations

More info can be found here: ----------Aerocharger Technology Page----------

Enough about us, moving on to our Spyder turbo kit. At first we didn’t think there would be a big enough market to justify us building a kit for these bikes. But after seeing the cult following these bike have created, we couldn’t help but get involved. We certainly like the bold design of these bikes, but even more so we like the design of the exhaust which makes it perfect for a turbo conversion.

We decided to maintain the factory double-wall header pipes for heat management and ease of installation. With that out custom ceramic-coated down-pipe slides right into the factory location, which puts the turbo where the base of the factory muffler would be. Exiting out the turbo is our ceramic-coated muffler section. Already bought a custom exhaust for your Spyder? Chances are you can have a local exhaust shop cut and weld it onto our system if you like. Otherwise you can enjoy our stealth black muffler, which is arguably the best sounding exhaust for the Spyder.

Up front we have our custom air box and blow-off valve assembly. All designed for the best throttle response and drivability. You can also see the Aero-Commander fuel control box here. The Aero-Commander comes pre-tune with a fuel map but also allows for fine-tuning and on-the-fly adjustments to ensure you get your Spyder dialed-in to your specific riding style, elevation, local fuel quality, etc.

All of our intake side components are black powder-coated aluminum. Our air boxes & intercoolers are TIG welded in-house and all pipes are bead-rolled for a snug & secure fit.

All of our exhaust side components are satin black ceramic-coated for the best heat management and a stealth look. Even our turbos are black ceramic coated.

On top we have an AEM’s digital wide-band oxygen sensor gauge displaying your air/fuel ratio in real-time with both a digital and “analog” output in one gauge. Opposite the AEM is a VDO 0-15psi boost gauge to let you know when to hold on tight.

All in all this is one of our favorite kits. It’s a clean package with great results. You can expect 130-140wp with ease at 6psi with plenty of room to grow. We can also cater to those who have custom motor builds and may need a bigger turbo. Just give us a call and we can get a turbo matched to your engine.