Hoginedgewood

Member

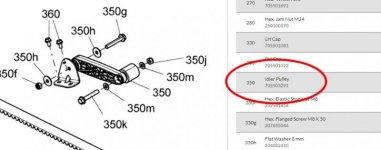

So I finally crawled around the f3s. It’s got a tensioner on the top of the belt. If I’m reading correctly this wheel won’t last long? I’m wondering why it’s on the top, seems like the top would be tight when accelerating, in some older HD applications guys will put a skate wheel on the bottom of the chain. This wheel on the top is throwing me.