JohnRtl

New member

Many thanks for all of the suggestions - all of which look to be very workable, but having the Satnav low down would be a last resort for me - so I've been investigating a few things in order to provide sockets for heated jackets; power and video cable routing for my Innovv K7 cameras and recorder; Satnav wiring; GPS (Zumo XT2) and handlebar controller wiring (I have a 2021 RT Limited).

The Satnav was the last thing to do, and here is the result.

First - A Rider's Eye View

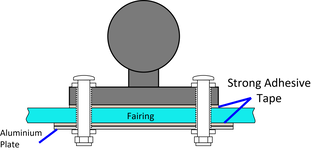

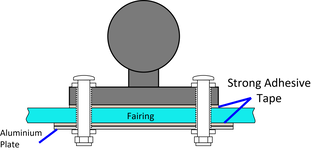

And a Side View of the RAM ball mount without the Zumo fitted. Viewed from the left hand side. The edge of the screen is on the left of the photo.

The cable that can be seen runs down to a tiny gap between the fairing and the mirror housing. There is plenty of room in the area under the fairing behind the screen, and it emerges behind the lower left speaker and into the quite large void in front of the speaker and behind the left hand side black panel. The wires from the handlebar controller are easily fed down the cable loop for the left hand controls and they too emerge into the same gap.

I used some very strong 'Mammoth' double sided tape. I've used it before for camera mounts and it was still holding things firmly when I tried to remove the camera mounts fro my previous bike. The Tape had remained flexible and although I could not pull the tape off, it was possible to slowly roll it off - encouraging it with thumb pressure from the side. It came off with some resistance, but cleanly. I have no thumb prints left though ! Whatever - it seems to be strong enough to do the job.

The tape was secured to the bottom of the ram ball mount. The Ram ball mount is a Garmin one that is normally attached to the rear of the satnav mount. This was pinched from my old 660 mount, so I am not going to miss it. I cut a plate from some aluminium sheet and that was stuck to the underside of the thick grey plastic console fairing with some more tape. This fairing is made of a quite thick, 'flexible' plastic - it's about 5mm thick. It has a certain amount of 'give' in it, but is certainly not brittle like the side faring panels on the RTL.

The bolts hold it all together, but they are not clamping the ram ball mount particularly tightly. The nuts have a Nylock insert so they don't need to be very tight, just snug. THay will not undo by themselves. The aluminium plate will spread the load of the nuts and washers. The double sided tap will act as a cushion and keep everything from rubbing against each other. The 4 bolts just stop it from ever becoming unstuck!

Holes in the fairing? Yes, there are four of them, but they are hidden by the mount and the bolts. What if I want to sell it ? That's easy - I sell it with the RAM ball in place. I've had 4 Honda Pan Europeans and I have parted company with all of them with a RAM ball mounted. Exach time, the buyer has found that to be very useful.

I need to experiment with the position. The short arm doesn't give a great deal of movement between the console fairing on which it is mounted, and the screen in its full range of movement. The left hand edge of the XT2 also extends beyond the outer edge of the screen. I think a longer arm will cure that, but it might vibrate a little more. Of course I had carried out position experiments beforehand. Where it is, will do nicely. I can now find out if there is a slightly better location available without it kncoking against the screen.

The handlebar controller - I was uncertain as to how much cable I would have left - so I mounted it close to the centre. In fact, there was plenty left, so I have room to adjust that position - closer to the left handlebar cuff.

The biggest problem encountered was removing the screen mechanism. The screen came off very easily and reveals a very sturdy cast alloy mounting bracket that is hinged on three hollow brass pivot rods/tubes. The inside is threaded and there is a bolt screwed into the rod from each side. That brass tube is not supposed to be tightly clamped, but it was. It must have been putting a fair bit of strain on the electric motor becasue the movement was stiff.

The screws came out OK - they clearly had thread locking compound on them, but the brass rods would not shift. I had to draw them out. Ask if you want to know how, but it took a while. The problem was that the alloy hole through which the brass bolt passes was corroded. White aluminium oxide powder. The rod could not turn and it certainly didn't slide through the hole as it should. The brass cleaned up OK and the holes were reamed out with an 8mm drill bit inserted all the way through and twisted between thumb and finger. Needless to say, these were greased on reassembly. I think there was a plastic sleeve in one hole, so I used a silicone grease.

-

-

Left image - the longer central bush which connects to the main motorised lifting arm - cleaned up and partially inserted.

Above right - Drawing out the threaded brass bush. The long 5mm bolt is screwed into the threaded bush. The 5mm nut is tightened to drawn out bringing the 8mm dia brass rod. The large nuts have a 10mm bore so the brass rod will pull through the hole.

The white powder on the photo is there from the Aluminium Oxide corrosion.

I've installed electrics for the satnav, heated jackets, and for front and rear video cameras, and took loads of photos. Just ask.

The Satnav was the last thing to do, and here is the result.

First - A Rider's Eye View

And a Side View of the RAM ball mount without the Zumo fitted. Viewed from the left hand side. The edge of the screen is on the left of the photo.

The cable that can be seen runs down to a tiny gap between the fairing and the mirror housing. There is plenty of room in the area under the fairing behind the screen, and it emerges behind the lower left speaker and into the quite large void in front of the speaker and behind the left hand side black panel. The wires from the handlebar controller are easily fed down the cable loop for the left hand controls and they too emerge into the same gap.

I used some very strong 'Mammoth' double sided tape. I've used it before for camera mounts and it was still holding things firmly when I tried to remove the camera mounts fro my previous bike. The Tape had remained flexible and although I could not pull the tape off, it was possible to slowly roll it off - encouraging it with thumb pressure from the side. It came off with some resistance, but cleanly. I have no thumb prints left though ! Whatever - it seems to be strong enough to do the job.

The tape was secured to the bottom of the ram ball mount. The Ram ball mount is a Garmin one that is normally attached to the rear of the satnav mount. This was pinched from my old 660 mount, so I am not going to miss it. I cut a plate from some aluminium sheet and that was stuck to the underside of the thick grey plastic console fairing with some more tape. This fairing is made of a quite thick, 'flexible' plastic - it's about 5mm thick. It has a certain amount of 'give' in it, but is certainly not brittle like the side faring panels on the RTL.

The bolts hold it all together, but they are not clamping the ram ball mount particularly tightly. The nuts have a Nylock insert so they don't need to be very tight, just snug. THay will not undo by themselves. The aluminium plate will spread the load of the nuts and washers. The double sided tap will act as a cushion and keep everything from rubbing against each other. The 4 bolts just stop it from ever becoming unstuck!

Holes in the fairing? Yes, there are four of them, but they are hidden by the mount and the bolts. What if I want to sell it ? That's easy - I sell it with the RAM ball in place. I've had 4 Honda Pan Europeans and I have parted company with all of them with a RAM ball mounted. Exach time, the buyer has found that to be very useful.

I need to experiment with the position. The short arm doesn't give a great deal of movement between the console fairing on which it is mounted, and the screen in its full range of movement. The left hand edge of the XT2 also extends beyond the outer edge of the screen. I think a longer arm will cure that, but it might vibrate a little more. Of course I had carried out position experiments beforehand. Where it is, will do nicely. I can now find out if there is a slightly better location available without it kncoking against the screen.

The handlebar controller - I was uncertain as to how much cable I would have left - so I mounted it close to the centre. In fact, there was plenty left, so I have room to adjust that position - closer to the left handlebar cuff.

The biggest problem encountered was removing the screen mechanism. The screen came off very easily and reveals a very sturdy cast alloy mounting bracket that is hinged on three hollow brass pivot rods/tubes. The inside is threaded and there is a bolt screwed into the rod from each side. That brass tube is not supposed to be tightly clamped, but it was. It must have been putting a fair bit of strain on the electric motor becasue the movement was stiff.

The screws came out OK - they clearly had thread locking compound on them, but the brass rods would not shift. I had to draw them out. Ask if you want to know how, but it took a while. The problem was that the alloy hole through which the brass bolt passes was corroded. White aluminium oxide powder. The rod could not turn and it certainly didn't slide through the hole as it should. The brass cleaned up OK and the holes were reamed out with an 8mm drill bit inserted all the way through and twisted between thumb and finger. Needless to say, these were greased on reassembly. I think there was a plastic sleeve in one hole, so I used a silicone grease.

-

-

Left image - the longer central bush which connects to the main motorised lifting arm - cleaned up and partially inserted.

Above right - Drawing out the threaded brass bush. The long 5mm bolt is screwed into the threaded bush. The 5mm nut is tightened to drawn out bringing the 8mm dia brass rod. The large nuts have a 10mm bore so the brass rod will pull through the hole.

The white powder on the photo is there from the Aluminium Oxide corrosion.

I've installed electrics for the satnav, heated jackets, and for front and rear video cameras, and took loads of photos. Just ask.

Last edited: