I've modified my suspension to allow camber/caster change.

To do that I used a lathe, stainless bolts and nuts and drill bits.

Bolts used to hold A-arm are M10 metric. Steel sleeve in a-arm has OD of around 14,6mm and 10mm ID.

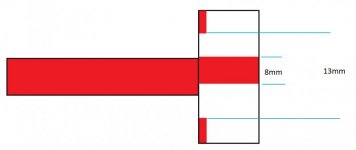

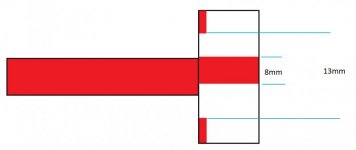

I've redrilled holes in plates on frame which are holding bushings and a-arm. They are now 13mm instead of 10mm. On lathe I've used big bolt M14 and drilled 8mm hole through top of the bolt with 2,5mm offset from center. I've also cut 2mm wide groove to have 13mm dimension at beginning of top part of this bolt. This 13mm dimension will later go inside places on frame.

I've made new sleeves with 14,7mm OD and 8mm ID. Bolts holding A-Arms are strong M8 12,9 (metric). So now I have 8mm bold which could be moved within round area of 13mm diameter.

Now I can move a-arm +/-5mm which gives plenty of room to change both caster and camber. Also, holes in frame were drilled with special drill to allow drilling in inside part of plates in frame. This is because top a-arms are bolted to part which holds the wheel, and you could use spacers to have negative camber. In my case bottom a-arm could be +2,5mm from center of frame and top -4,5mm which is total of 7mm of "travel".

I've bought spyder damaged in accident and repaired averything I could with cheap parts from other cars and used solutions well known in "industry" like case above. My previous project was using BMW FS650 and using whole suspension from KTM 640 to have ultimate enduro. Now me and my wife are a little bit heavier so spyder could be potential touring machine for us but it needs to be: 1. cheap, 2. configurable, 3. user friendly (no limp mode in ANY case). Let's see how it goes.

If somebody have some requests regarding some measurements I can do that .

.

BTW, I've used master cylinder from citroen and modifed brake reservoir to work with original one from can am.

To do that I used a lathe, stainless bolts and nuts and drill bits.

Bolts used to hold A-arm are M10 metric. Steel sleeve in a-arm has OD of around 14,6mm and 10mm ID.

I've redrilled holes in plates on frame which are holding bushings and a-arm. They are now 13mm instead of 10mm. On lathe I've used big bolt M14 and drilled 8mm hole through top of the bolt with 2,5mm offset from center. I've also cut 2mm wide groove to have 13mm dimension at beginning of top part of this bolt. This 13mm dimension will later go inside places on frame.

I've made new sleeves with 14,7mm OD and 8mm ID. Bolts holding A-Arms are strong M8 12,9 (metric). So now I have 8mm bold which could be moved within round area of 13mm diameter.

Now I can move a-arm +/-5mm which gives plenty of room to change both caster and camber. Also, holes in frame were drilled with special drill to allow drilling in inside part of plates in frame. This is because top a-arms are bolted to part which holds the wheel, and you could use spacers to have negative camber. In my case bottom a-arm could be +2,5mm from center of frame and top -4,5mm which is total of 7mm of "travel".

I've bought spyder damaged in accident and repaired averything I could with cheap parts from other cars and used solutions well known in "industry" like case above. My previous project was using BMW FS650 and using whole suspension from KTM 640 to have ultimate enduro. Now me and my wife are a little bit heavier so spyder could be potential touring machine for us but it needs to be: 1. cheap, 2. configurable, 3. user friendly (no limp mode in ANY case). Let's see how it goes.

If somebody have some requests regarding some measurements I can do that

BTW, I've used master cylinder from citroen and modifed brake reservoir to work with original one from can am.