Part 1

I had a feeling you would ask that question, so now is a good time to talk about this. Kinda long explanation, though, but I don’t know any other way to do this than give you the full download.

Modern day fuel injection systems have two modes - closed loop and open loop operation. If you understand the basics off how your cruise control works, then you understand closed loop operation. For example, you set a target speed, or a “set point”, for what you want the speed to be. You have a control system that controls a process to try to maintain that speed - in this case operates the throttle and thus rear wheel RPM, and you have a sensor to feedback to the controller whether it’s operating at, above, or below that set point. Same with electronic fuel injection. The target AFR , the set point, for the air-fuel ratio (AFR) is provided to us already programed into the ECU. It’s fixed at 14.7:1. 14.7 pounds of air to 1 pound of fuel. The process we’re controlling is exhaust gas O2 by controlling fuel flow; and our O2 sensor feeds back to the ECU whether we are at, above, or below set point. At 14.7:1 the O2 sensor output voltage is around .45 volts. Leaner and the voltage goes down, richer and the voltage goes up. The ECU is programmed to automatically maintain that .45 volts.

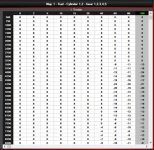

Programed into the ECU is a baseline fuel map looking very much like the Power Commander (PC) Map. It’s called a lookup table and contains values that correspond to the turn on duration time of the fuel injectors. The ECU interpolates between the squares so that there is a smooth transition across the operating range. The baseline map is OK for the perfect engine on the perfect day. In the real world, ambient conditions change, filters slowly get clogged, fuel pressure changes, the purge valve opens and closes, etc. So, the ECU needs a way to fine adjust the fuel delivery from the fuel map in order to maintain the AFR at set point. That function is called fuel trim, and it operates continuously making little adjustments based on feedback from the O2 sensor. So, like your cruise control is constantly making little adjustments to the throttle to maintain rear wheel RPM using that signal from the speed sensor, the ECU is constantly making little adjustments with fuel trim to try to maintain .45 volts coming from the O2 sensor.

So, let’s say we get a small crack in a vacuum hose or we install a free flowing air filter, or exhaust. This results in higher airflow through the motor and thus a leaner AFR - let’s say it becomes 14.8:1 - meaning that there will be more O2 in the exhaust, Sensing this, the output voltage of the O2 sensor goes down. The ECU sees that decrease in voltage and increases the fuel trim amount, adding slightly more fuel which compensates for the additional air, thus restoring the AFR back to set point as sensed by the O2 sensor. The end result is that the AFR has been restored back to 14.7:1, the fuel trim value is slightly more positive than it was before, and it’s all completely invisible to the operator. If we get a real large vacuum leak for example, the same thing happens except that the fuel trim function may reach the limit of it’s range. Around 10% for the Spyder. If the fuel trim reaches it’s limit and still has been unable to return AFR back to set point as sensed by the O2 sensor voltage, it’s then that we get the lean code tripped. Because it’s then that we have a lean condition that can’t be corrected.

The main take away is that the lean code is not tripped unless the fuel trim function CANNOT restore the actual AFR back to our target AFR - our set point - before it reaches the limit of it’s range. So, what’s all this have to do with a Power Commander? We’re getting to that. So far, we just need to get an understanding of how closed loop operation occurs during a change.

ray:

ray: