NEXUS

Member

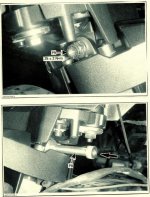

I have a question on the Tri Axis Adjustable Handlebars to someone that has installed them.

What would cause the bolt holding the handle bars to come out and nut to fall off ?

I have looked for a parts break down with no luck or instillation guide.

Does the nut on the bolt that holds the handle bars in a nylon lock nut?

I had a very close call happen to me this weekend and am trying to understand what could

have caused this to happen other than the nut was not tighten. :yikes:

I did not install them it was put on a 2014 RT at the dealer.

Anything would be helpful

Thanks

Nexus

What would cause the bolt holding the handle bars to come out and nut to fall off ?

I have looked for a parts break down with no luck or instillation guide.

Does the nut on the bolt that holds the handle bars in a nylon lock nut?

I had a very close call happen to me this weekend and am trying to understand what could

have caused this to happen other than the nut was not tighten. :yikes:

I did not install them it was put on a 2014 RT at the dealer.

Anything would be helpful

Thanks

Nexus