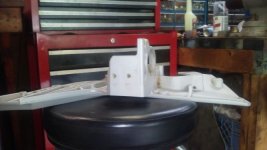

I am building a hydraulic hand brake assist for my 2010 RT. The master cylinder is mounted and turned out to be a bit of work but a very neat installation. I can provide pics and info if anyone is interested.

I am now at removing the large aluminum casting to which the footpeg, floorboard, and brake pedal are mounted. I have removed all of the bolts. It is loose. I cannot remove it. There is something behind the brake slave cylinder that is restricting the removal. The next logical thing for me to do is to crawl under and see if I can determine the restriction.

I am somewhat phisically handicapped, but I can do this. I just thought that if someone on here is experienced with this, I could save some time and discomfort.

Any ideas ?

I am now at removing the large aluminum casting to which the footpeg, floorboard, and brake pedal are mounted. I have removed all of the bolts. It is loose. I cannot remove it. There is something behind the brake slave cylinder that is restricting the removal. The next logical thing for me to do is to crawl under and see if I can determine the restriction.

I am somewhat phisically handicapped, but I can do this. I just thought that if someone on here is experienced with this, I could save some time and discomfort.

Any ideas ?