View Poll Results: How often do you check your windshield mount?

- Voters

- 347. You may not vote on this poll

-

Windshield mount, what are you talking about, I NEVER check it.

-

I only check it durring routine maintenance.

-

Mine hasn't broke, but I still check it before every ryde.

-

Mine broke, so I check the new one every time I go for a ryde.

-

07-01-2013, 09:36 AM

#126

And BRP is closed today...

Happy Canada Day to our Northern Friends!

-

07-01-2013, 10:37 AM

#127

Active Member

Originally Posted by CyncySpyder

The windshield of the RTs are held by three points. Two points are pivot points & the third, which is in the center of the shield, is the dog-boned shaped metal adjustment mechanism that actually goes up & down with the press of your button on the RECC. Its that metal, dog-boned shaped mechanism that is failing, usually with a noticable crack half way thru, before it actually gives, and cracks all the way through. Just keep an eye on yours. If it breaks, a hose-clamp can offer a temporary fix. But ryding with it broke, isn't advisable as the shield is laying on top of your dash, & with any wind turbulance, you'll end up needing a new shield.

Mine broke right after i got on the highway. The windshield folded back on the dash. I was able to get turned around and limp back to the house. Checked with the dealer and BRP covered it under warranty. They sent the whole assembly that has the motor and all three arms on it. I was scheduled to leave on an out of town ride the next day so I took the arm off and went to a weld shop and they were able to weld the arm for me for $40. It worked fine for the trip and then I changed the whole part when I got back. Kept the old for a spare though.

James

-

07-01-2013, 11:03 AM

#128

You have a spare???

-

07-01-2013, 11:05 AM

#129

Very Active Member

-

07-01-2013, 12:28 PM

#130

-

07-02-2013, 09:23 AM

#131

Very Active Member

Modified middel bracket wtih Zip ties to give extra strength Modified middel bracket wtih Zip ties to give extra strength

Having posted I have now had my Windshield Middle bracket and Motor replaced for a 2nd time

I decided to add some Zip ties to give some extra strength to the Middle bracket and I have also fitted the new lighter 23" OEM Vented Windshield, In the hope this will avoid any further issues with a broken Middle bracket

Should someone come up with a stronger bracket I would go for it

This is what I did :-

Stripped down the front end to allow access to the Windshield Motor unit

Added some 3mm thick Foam Rubber where the Miiddle bracket rests on the housing, to act as a dampener to reduce any vibration whilst the Windshield is in the down position

Used a Large Zip tie 500mm x 9mm to go around the complete Middle bracket - End cut off after the zip tie was pulled tight

2 Smaller Zip ties used at each end of the Middle bracket to ensure the Large zip tie could not slide off the Middle bracket

These smaller zip ties were turned around so they did not catch the Windshield Motor unit cover plate

Tests carried out to ensure the Windshield still had full movement and did not catch anywhere

No problems so I fitted the new 23" Vented Windshield, further test carried out and again the Windshield still has full range of movement and the operation is smooth as per standard

Once I was happy I used a carbon fibre wrap as supplied by Inspector Gadget for Windshields

This hide any view of the Zip ties from the outside

(Note - Windshied removed to do the wrap to avoid any strain on the Windshield when fitting it)

I have posted some pictures in the Album Gallery to show the above - See

http://www.spyderlovers.com/forums/a...p?albumid=2914

Eddie Sheppard

Poole Dorset UK

Get a Spyder - See the World

-

07-02-2013, 10:00 AM

#132

Teddys favorite human

Here are some pics if you were to take the mount apart***NOT SUGGESTED*** Here are some pics if you were to take the mount apart***NOT SUGGESTED***

-

07-02-2013, 11:00 AM

#133

Thanks Dave!

-

07-02-2013, 11:19 AM

#134

Very Active Member

Originally Posted by CyncySpyder

Have to agree with you ref ***NOT SUGGESTED***

Was temped to open up mine (The broken one that is) but not that brave

I would not be sure how to ensure the shaft is put back in the right place to ensure the arm would stop at both its upper and lower setting - Maybe it has to be set up in BUDS Which we would not have access to

I suppose if you marked the shaft and the shaft housing it may be ok but its not something I could be sure of

Perhaps others looking at your photos could give advice

Just another question

Someone posted they had managed to get it welded but as mine is broke at the Windshield end would a weld affect the bushings inside

Dave - Thanks for posting the Photos of the insides anyway it gives us more knowledge

Eddie Sheppard

Poole Dorset UK

Get a Spyder - See the World

-

07-02-2013, 12:42 PM

#135

Very Active Member

Originally Posted by CyncySpyder

If the idler bearing is a press fit on the hex shaft then making a replacement part would not work.

Thanks for the photos.

JT

-

07-02-2013, 01:30 PM

#136

-

07-02-2013, 02:38 PM

#137

Very Active Member

Nice! See if they will let you keep the old unit...

JT

-

07-02-2013, 02:46 PM

#138

-

07-08-2013, 06:30 PM

#139

Cracked windshield mont Cracked windshield mont

-

07-09-2013, 07:27 AM

#140

Teddys favorite human

Pics of the plastic/nylon sleeves we were discussing Pics of the plastic/nylon sleeves we were discussing

-

07-31-2013, 01:19 PM

#141

Very Active Member

BRP UK accept my claim BRP UK accept my claim

With reference to my earlier posts

I am pleased to report BRP UK has accepted my claim and I am getting a refund for the Parts replaced

see this thread

http://www.spyderlovers.com/forums/s...146#post665146

Thanks to all those that posted on this item as it was good evidence to support my case and again well done

BRP for doing the right thing and stepping up to the Plate

Eddie Sheppard

Poole Dorset UK

Get a Spyder - See the World

-

10-17-2013, 02:44 PM

#142

Add Me to the List Add Me to the List

Add me to the list of owners with broken windshield mounts. I tried to go back and re-vote in the poll but couldn't find a way to do it. I've seen several threads on this, one new one just today, but thought I'd post on this one as it seems to be the main thread on the subject.

We were pleasantly cruising up the Natchez Trace Parkway at 50 mph near Tupelo when wham, the shield flew what seemed like out, up, and then settled in "against" the bike. About 1200 miles from home in eastern PA. After calling a dealer east and west of our location, who weren't very helpful, we called north to Nashville and got a great dealer there -- America's Motorsports 8th Avenue. He overnighted the part and when we arrived there the next day was waiting for us and had us fixed and out the door in no time. We paid the fee for overnight delivery and BRP

picked up the rest under warranty. 100_0794.jpg100_0796.jpg

($573 for the part (complete assembly) and 0.5 hours for installation. They aren't cutting the dealer any break on installation time!)

Now the bad news is riding over 200 miles in that condition. (My temporary repair lasted five miles.) The broken shield directed air right to my helmet opening making for incredible wind noise. If I stretched way up tall (I'm 6'1") I could get the air at my throat which reduced the noise but wasn't exactly pleasant. My wife said the back seat was no place to be either. The good news is that most of our 200 miles was at 50 mph with no traffic at all on the Trace. On an interstate when a semi blows by you at 70 mph, all heck breaks loose. Not good. Fortunately we had only about 20 miles of that. After the first semi passed us, I made sure I stayed ahead of all the others. Further good news -- it wasn't raining.

I am totally disappointed in that the new part has the same part number as the OEM part when the bike was built -- we have a 2011 RT-S. I can't believe that BRP has not remedied this serious deficiency. To keep supplying the same part over and over and having it fail is beyond my comprehension. Now that I'm home, I plan to install the updated pins and bolts but I'm not at all sure that will really prevent future failures. I think it may just eliminate a few rattles from the pins not being secure. The 2011's already have the bushings on all three arms that others have talked about and the assembly comes with new ones for the center support anyway.

I will make a separate thread with more about our excellent experience with the dealer. I want to get the attention of whoever it is that keeps the spreadsheet of good dealers and make sure America's Motorsports in Nashville gets added to the list.

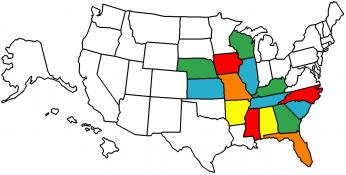

RT and Gold Wing States & Provinces

-

10-17-2013, 08:08 PM

#143

Motorbike Professor

That is an odd-shaped break. Not at all what I would expect. It appears to have been twisted or heavily side-loaded. There is something going on with these that is not obvious.

-Scotty

2011 Spyder RTS-SM5 (mine)

2000 BMW R1100RTP, motorized tricycle & 23 vintage bikes

2011 RT-622 trailer, Aspen Sentry popup camper, custom motorcycle trailer to pull behind the Spyder

Mutant Trikes Forever!

-

10-17-2013, 08:30 PM

#144

Very Active Member

Got mine back today Got mine back today

It's fugly as mentioned in another post, but it is re installed and action is normal.Will remount windshield shortly and test action fully. DSCF1594.jpg

Now, what's this about updated mounting hardware? I was going to shim around the pins with Teflon washers to reduce some inherent slop(at least on my 2011) and reduce what has always been some side to side movement. Yes, I intend to live with this awhile. And a Laurel and Hearty handshake to those who have braved this before me! Patrick

2011 RTS 2006 Yamaha Morphous

2017 F150 2015 MINI Cooper S IBA 56167

-

10-17-2013, 09:00 PM

#145

Very Active Member

A possible failure theory A possible failure theory

Lots of great info in this tread; good to see so many owners diving in to work this obvious issue.

Three observations:

1. How the motorized function operates: No one commented on how the mechanism raises/lowers the windscreen. I was looking into modifying mine until I studied it. When you raise the windscreen, the dogbone part rotates. That is, it doesn't go straight up/down. You can see the windshield actually tilts as the dogbone rotates. When down, the windscreen has a more vertical profile. As you rotate the dogbone, the windscreen slightly raises, then tilts back as you continue to rotate it. Once over half way, you can see the dogbone starts to push the windshield up and it tilts the windscreen more upright. I believe he aerodynamic force on the windscreen vary with the angle of the windscreen for a given speed. The more upright the windscreen, the greater aerodynamic loading.

2. Vibration: Due to the lower drive belt tension, there are certain RPM ranges that allow the belt to vibrate. This vibration travels throughout the bike. Having ridden 780 miles in one sitting at 75 MPH, my hands were NOT happy. I have since added the SMOOTHSPYDER belt tensionior and this has almost eliminated the vibration. Point is, this vibration coupled with the windshield at a position with a high aerodynamic loading is a bad combination. In this condition, the dogbone is taking a real pounding; the wind is pushing the top of the windshield back and the dogbone is holding it back - BUT - it is really shaking due to the vibration. When you look at where the cast part is failing you can see that is where the load is the greatest as the base is connected to the motor transmitting the vibration load up the length. The aerodynamic load is coming back the other way. The dogbone has the most give on that end, so that is where the fatigue failure is showing up.

3. Position of dogbone part: I am sure there is a point in the rotation where the loading is the worse (aerodynamic and vibration). I think you might be able to figure it out looking at where it is failing. I'll go back and look at the pics and post back after looking at mine through its range of motion.

For me, I run my windscreen where it has the greatest tilt as it should have the least aerodynamic loading. It is low enough that I can look over the top (I'm 5' 11") and the wind is not a problem. In retrospect, this might place the dogbone in the most vulnerable position, so I have to look at this. That said, the tensioner has eliminated the big vibration problem.

So, I'd be interested in reposts by people who had the failure to see if there is a commonality:

1. Do you have the [belt] vibration problem (you do not have a belt tensioner)?

2. Has you drive belt tension been reduced per the new spec (to avoid the early bearing failure)?

3. What position do you normally keep the windshield at (especially at highway speed)?

3. What is your normal highway speed?

4. How much of your riding is at highway speeds?

I'll guess the common combination is vibration (no tensioner) + lots of highway speed + certain position of the dogbone + lower drivebelt tension = failed dogbone part.

If someone can have a new dogbone part made eliminating the cast aluminum part, I would suggest a slightly longer length. This will allow down or up potential or greater tilt to further reduce drag. I think anything we can do to reduce drag will help MPG...

Jerry

Last edited by spacetiger; 10-17-2013 at 09:04 PM.

-

10-18-2013, 05:25 AM

#146

Teddys favorite human

Jerry, really good Observations & thanks for taking the time & interest in this Jerry, really good Observations & thanks for taking the time & interest in this

Originally Posted by spacetiger

So, I'd be interested in reposts by people who had the failure to see if there is a commonality:

1. Do you have the [belt] vibration problem (you do not have a belt tensioner)? No tensioner, some vibration

2. Has you drive belt tension been reduced per the new spec (to avoid the early bearing failure)? Yes

3. What position do you normally keep the windshield at (especially at highway speed)? Raised to max with one bump down

3. What is your normal highway speed? 70-75 with infrequent triple digits

4. How much of your riding is at highway speeds? Over half, usually a minimum of 40 miles per day

I'll guess the common combination is vibration (no tensioner) + lots of highway speed + certain position of the dogbone + lower drivebelt tension = failed dogbone part.

It would seem, at least in our case, your observations are spot on

I think anything we can do to reduce drag will help MPG...

While this is proven and does seem logical in general terms, so far, our personal experience is telling us otherwise, at least concerning our shields. I realize there are so many variables to deal with, but a little over 3 weeks ago, we switched to a Cal-Sci Tinted Shorty shield, which I'm thinking may just be the smallest shield on the market at this time made specifically for an RT Spyder & I track every fill up & haven't noticed any change at all in our MPGs

Fully Lowered Fully Raised Fully Raised

Again, so many variables to deal with concerning this matter, but I'd also be curious how many others that have had issues have also done mods to their suspensions or after-market/NON OEM tires? Like we personally have Elka Shocks & are also running car tires as well

-

10-18-2013, 06:33 AM

#147

Very Active Member

A couple of other thoughts:

This problem was first posted in Dec 2011. I think the RT-S came out as a 2010 model. So that is almost 1.5 to 2 years before this problem pops up. Since the first problem, there has been quite a few problems noted with cracked dogbones; some have experienced this twice within a short period of time. Something has changed to cause this problem.

After my 500 mile service, I noted the vibration issue. I later found out the dealer adjusted my belt tension as part of the change to avert the early rear wheel bearing failures. When I ride for only about an hour, the vibration is tolerable. But on straight line riding for 13 hours, it gets to the body. I can only imagine what the cumulative affect would be to parts on the bike. You can ride lots of 1 hour trips and get by with the vibration - but to the parts, this is a cumulative stress. Eventually, the part will experience x,xxx,xxx vibration cycles - then fail. When the part starts to go, it goes quickly. I would say this is a classical case.

So, I think you can cross correlate the belt tensioner change to this dogbone failure. That is, within X months of making this a factory notice and dealers making the belt change, this problem surfaced X months later. Rider speed, shield location, and total cumulative time in the "bad vibration zone" are the variables between the different failures. In the end, I think you can narrow the total number of vibration cycles to failure.

If true, then BRP caused these failures by specifying the belt tensioner change and shoud cover the cost of repairs even if it is out of warranty because they are telling the dealers to change the belt tensioner. Eventually, all bike will have the belt tension changed if they have their bike serviced by the dealer - I suspect in these cases, almost everyone will have this part fail. Only the rider that avoid the belt vibration rpms's will avoid this problem.

New questions for the people who have experienced this failure:

5. Did you get the bike serviced (and have the belt tension reduced) prior to the dogbone failure?

6. If so, how many months prior to the failure did you have the bike serviced?

7. How many miles did you ride from the time of the service (should be on the receipt) and what was the odometer reading at failure?

We might be able to collect enough data to narrow the cause and time to failure...

Jerry

Edit:

I should say, the sooner we collect this data and document the connection, the sooner BRP will have to act. We have been asking for a new dogbone part that is stronger. I think BRP will have to develop this and may have to throw in a belt tensioner. I included the belt tensioner because changing the dogbone may not solve this problem. All it does it transfer the failure to the next weakest link as the cause (vibration and aerodynamic loading) will still be there. BRP has to act because this could fail at a bad time causing a loss of life. Once documented and made aware, BRP becomes liable as does all the dealers making the belt tensioner change. The first death could trigger a big legal mess for all. BRP would act quickly I am sure to avoid this mess, so start posting the answers to the 7 questions and I'll make and post the graph showing the correlation. Once we get about 10 data points, we can submit a letter to BRP and add to it as more riders come forward.

Last edited by spacetiger; 10-18-2013 at 07:06 AM.

-

10-18-2013, 02:13 PM

#148

Updated Hardware Parts List Updated Hardware Parts List

Originally Posted by Pandy

Now, what's this about updated mounting hardware? I was going to shim around the pins with Teflon washers to reduce some inherent slop(at least on my 2011) and reduce what has always been some side to side movement. Patrick

I just ordered the parts. Not at all sure it will prevent the breakage but if it eliminates some shakes and rattles it will be a good thing. My 2011 came with the "sleeves" that fit on either end of the pin to prevent metal-to-metal contact. But the replacement center strut assembly came with new sleeves installed so I decided to order new sleeves for the side struts as well. You need a pair for each pin or strut. Here's my order list:

705005974 "axle assembly" or "retainer pin" in the diagram. 1 needed for the center strut $7.99

705005973 "axle assembly" or "retainer pin" in the diagram. 2 needed for side struts $7.99 each

705003267 "sleeve" 6 needed to do all three struts. I needed four. My dealer didn't think they came in pairs so I ordered four but I think I might be getting four pairs. $5.80 each (or pair?)

250000565 "screw torx" or "hexalob screw M4 x 10" in the diagram. 3 needed for 3 struts. $1.99 each

705005666 "bumper" or "windshield rubber bumper" in the diagram parts list. I couldn't find them in the diagram but am hoping maybe they are bumpers that fit on the fixed stop that the arm rests on when lowered. I'll see what they are when I get them. The parts list says 2 are required. $.99 each

That's it as far as I can figure out. If not, I'm sure others will chime in with their info. All this comes from the on-line parts catalog on the BRP site. I looked at 2012 models under "body and accessories console". Study the diagram carefully as it's one of the more difficult ones to interpret.

Last edited by gypsy_100; 10-18-2013 at 02:16 PM.

Reason: added comment

RT and Gold Wing States & Provinces

-

10-18-2013, 06:11 PM

#149

Very Active Member

Cheap Fix for the Slop/Rattle Cheap Fix for the Slop/Rattle

Originally Posted by Pandy

It's fugly as mentioned in another post, but it is re installed and action is normal.Will remount windshield shortly and test action fully. DSCF1594.jpg

Now, what's this about updated mounting hardware? I was going to shim around the pins with Teflon washers to reduce some inherent slop(at least on my 2011) and reduce what has always been some side to side movement. Yes, I intend to live with this awhile. And a Laurel and Hearty handshake to those who have braved this before me! Patrick

Get a couple nylon ties; those tiny skinny ones about 4-5" long. Pull one up tight on the outside of the two support bars where there's an amount of slop. Stopped the rattle in mine.

Two Wheelers from 1963-2011

Three Wheelers:

2011 RT(Red)

2014 RT(white)

2016 F3T(red)

2022 RT current ride(silver)

__________________

2016 Slingshot

2018 Vanderhall

2019 Slingshot

-

10-18-2013, 07:19 PM

#150

Very Active Member

CyncySpyder ,

On the smaller windshield and better MPG, I would say it is all drag related. The smaller windshield does not necessarily mean lower drag, it is just potentially reduces the overall surface area of the entire bike. I say potentially reduces the surface area. Keep in mind the rider/passenger and top back end of the bike are part of the surface area. You want the windshield to create an airflow over the rider but do so so it can come back together smoothly behind you causing it to miss the rider etc. If your windshield is too small, the airflow hits the rider, etc, and the surface area goes way up.

The drag force (Fd) is calculated from this equation:

1/2 is a constant

p is the density of the fluid; in our case it is air

v is the velocity

Cd is the coefficient of drag

A is the surface area

You clearly have reduced A, the surface area with the smaller windshield/overall bike. That leaves only 2 other variables, v and Cd. Assuming you are still traveling at the same overall average velocity, it is the Cd of the entire bike that is the same.

The Cd of the bike is influenced by the windshield; but that does not mean smaller is better. The Cd of a flat plate going into the wind is 1.28. Go look at your shorter windshield. If you run it in the upright position, I bet it is more upright - closer to the flat plate example. A slight bend running from left to right helps reduce the Cd, but it still is high. Take a look at the GL1800 windscreen. It is really tipped over + it is curved from side to side. This canted and curve surface really helps drop the Cd. It also helps the airflow as it it is smoother coming over the top and around the rider/passenger. When you run a more vertical surface it creates a lot of induced drag as the air is not smooth but it can create a pocket of still air behind it. Good for the rider but not so for the passenger as the air comes slamming in behind the rider and hits the passenger... As I look at the bike, I see lots of winged surfaces that shape the airflow. Many of them are placed to divert air to the side creating pockets (vacuum) spots to pull heat away. Examples inclued the small clear wings in front of the top vents and the lower black wings to divert air outward to help pull heat away and channel air to push water from the front wheels. They do that well enough, but they add lots of induced drag. Stick your arm out sideways and then canted them back 30 degrees and note the [air] force on your arm. Canting back arm helps reduce the drag, but there is still a lot. Thats what your black side air deflectors are doing, diverting air and creating drag. Speaking of which the fenders are something else. Look at them at highway speeds. The mud flap shakes side to side. Why, they act like big scoops even though the tire is in front of them. The force on them is so great, they shake. You can see how they changed the 2013/2014 fenders. The back is shorter and canted front and rear lips to help air flow out. They also removed the outside side lip so the overall fender assembly doesn't act like a scoop. And the mirrors, nice big surfaces sticking out in the airflow. Air management was not a high priority on this bike design. There are so many poor air management design decisions that contributes to high Cd and hence poor MPG. I will be spending some time to work on this since I am an aerospace engineer. My targeted areas are fenders, mirrors, underside of the bike, windshield, and small wings. I am confident measurable gains can be made. As I make changes, I'll post the results in a separate thread.

A side comment on cooling/drag. As I look at the 2014 Spyder, they changed the radiators by moving them forward and increasing the surface area. This change solved 2 documented problem areas, take the heat away from the right foot and increased the capacity of the cooling system. I just wish they implemented a reduced profile. Look at the front; 2 large scoops in the front = high drag. Using the bigger radiators, one on both sides, they should have tilted back both radiators over at a 30 degree angle. The scoops could be smaller and the exit flow would be down and under the bike. At slow speeds, the fans would easily pull in enough air flow and at speed there would be plenty of airflow. They still don't have aero engineers helping them clean up the bike.

Jerry

Last edited by spacetiger; 10-18-2013 at 07:27 PM.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

|